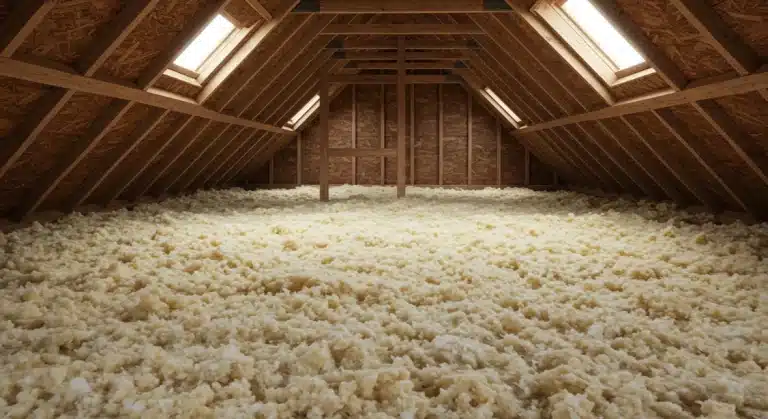

Blown-in insulation is widely used in both residential and commercial buildings due to its cost-efficiency and ease of installation. The two most common types are cellulose and fiberglass. Cellulose is made from recycled paper products, while fiberglass is composed of spun glass fibers. The main difference lies in thermal performance, moisture sensitivity, fire resistance, and material composition. Fiberglass typically offers slightly better fire resistance and is less prone to moisture absorption, while cellulose delivers superior air sealing and recycled content.

Professionals working in hot, humid regions like the Gulf Coast or cooler zones such as northern Florida often weigh moisture control and thermal resistance more heavily. This article breaks down the differences clearly, offering hands-on insights and performance data grounded in field experience.

Prestige Insulation Solutions brings years of direct installation experience across varied climates, housing types, and commercial structures. The comparisons below reflect field-tested observations and verifiable data.

Key Differences at a Glance

| Feature | Cellulose Blown-In | Fiberglass Blown-In |

|---|---|---|

| Material Composition | Recycled newspaper treated with borate | Spun glass fibers |

| R-Value per Inch | 3.2 – 3.8 | 2.2 – 2.7 |

| Moisture Sensitivity | Higher (can absorb moisture) | Lower (resists moisture) |

| Fire Resistance | High (treated with fire retardants) | High (naturally non-combustible) |

| Settling Over Time | Yes, around 20% | Minimal |

| Air Sealing Capability | Excellent | Moderate |

| Sound Insulation | Higher | Lower |

| Installation Method | Blown into cavities or attics | Blown into cavities or attics |

| Mold Resistance | Moderate | High |

| Environmental Impact | Higher recycled content | Lower recycled content |

Technical Specifications and Field Performance

| Specification | Cellulose | Fiberglass |

|---|---|---|

| Typical Density (lbs/ft³) | 1.5 – 2.0 | 0.5 – 1.0 |

| Coverage (per 30 lbs) | ~15–20 sq ft @ R-19 | ~60–70 sq ft @ R-19 |

| Vapor Barrier Needed | Often recommended | Often not required |

| Application Climate | Best in dry-to-moderate climates | Suited to all climates |

Source: U.S. Department of Energy, 2024; NAIMA Residential Insulation Report, 2023

Performance in Humid and Coastal Regions

In Gulf Coast climates, managing humidity is critical. Fiberglass resists moisture better and is less prone to mold, making it a safer choice for unventilated attic spaces. Cellulose, when exposed to moisture, may compact and lose insulation value faster. However, when properly sealed and vented, cellulose still performs well in moderately humid areas.

Bonus Tip: In homes near the coast, always pair insulation with proper attic ventilation and vapor barriers to reduce long-term performance issues.

Installation and Maintenance Insights

Professionals using blown-in cellulose often note its superior ability to seal gaps and irregular cavities, reducing air leakage and improving energy retention. However, cellulose tends to settle more over time and may require reapplication after 10–15 years. Fiberglass maintains its shape better but doesn’t provide the same level of air sealing without additional sealing products..

Things to Consider Before Making a Decision

- Climate and Moisture Exposure: Choose fiberglass for high-humidity regions and cellulose for dry zones.

- Existing Construction: For retrofit projects, cellulose adapts better to irregular shapes and cavities.

- Sustainability Goals: Cellulose has higher recycled content.

- Air Sealing Needs: Cellulose offers better air sealing.

- Longevity: Fiberglass retains performance longer without settling.

- Allergies/Sensitivity: Fiberglass can irritate skin and respiratory systems if not properly handled.

Relevant Services from Prestige Insulation Solutions

- Blown-In Insulation: Applied to attics or wall cavities for cost-efficient coverage.

- Fiberglass Insulation: Effective thermal control with lower moisture absorption.

- Insulation Removal: Safe extraction of damaged or outdated insulation.

- Roof Insulation: Specialized application for improving overhead thermal resistance.

Common Questions About Cellulose vs Fiberglass Blown-In Insulation

Which lasts longer, cellulose or fiberglass?

Fiberglass typically lasts longer with less settling over time.

Does cellulose insulation attract pests?

No, borate treatment in cellulose deters most pests.

Can I use either type in my attic?

Yes, but match insulation type with climate and ventilation.

Is one type safer for people with allergies?

Cellulose generally causes fewer irritation issues.

Get Expert Insulation Guidance

For expert recommendations tailored to your building, environment, and budget, contact:

Prestige Insulation Solutions Phone: (850) 429-4969 Email: [email protected]

Frequently Asked Questions

How often should blown-in insulation be replaced?

Every 15–20 years for cellulose; fiberglass may last longer if undisturbed.

Can insulation performance degrade over time?

Yes. Cellulose settles; fiberglass can compress or shift if disturbed.

What R-value should I aim for in Florida attics?

R-30 to R-38 is recommended in most of Florida.

Are both insulation types safe for homes with HVAC ducts in the attic?

Yes, with proper sealing and vapor barriers.

Does adding more insulation reduce energy bills?

Yes, improved thermal resistance reduces HVAC load and monthly costs.