Most negative information about spray foam insulation stems from poor installation practices or outdated data rather than the material itself. When installed correctly, spray foam offers superior energy efficiency, air sealing, and moisture resistance compared to traditional insulation options. This article breaks down the most common misconceptions and explains why they shouldn’t stop you from considering this effective insulation solution.

Years of hands-on installation experience reveal that these myths often prevent homeowners from making informed decisions about their insulation needs. Understanding the facts behind spray foam insulation leads to better choices for home comfort and energy savings.

Myth 1: Spray foam is always too expensive

While the upfront cost of spray foam exceeds fiberglass or cellulose, the long-term savings tell a different story. Spray foam reduces energy bills by 30 to 50 percent in most homes, paying for itself over time through lower heating and cooling costs. The material never needs replacement, unlike traditional options that settle and lose effectiveness.

A report from the U.S. Department of Energy shows that proper insulation, including spray foam, can reduce total home energy consumption by up to 15 percent when combined with air sealing. The initial investment recovers through monthly savings typically within five to seven years.

The total cost should include long-term operating expenses rather than just the installation price. Homes with spray foam insulation often require smaller HVAC systems due to reduced heating and cooling loads. This equipment savings offsets some of the initial foam cost. Insurance companies sometimes offer discounts for homes with superior insulation and fire-resistant materials.

Bonus Tip: Calculate the payback period by dividing the installation cost by annual energy savings. Most homeowners find the investment makes sense within a decade, especially in regions with extreme temperatures.

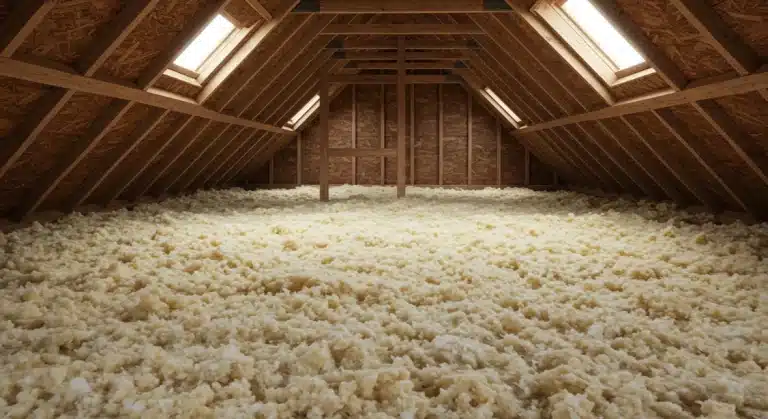

Myth 2: Spray foam causes roof rot

This myth confuses correlation with causation. Roof rot occurs when moisture gets trapped in unvented attic assemblies. Spray foam itself does not create moisture problems. In fact, closed-cell spray foam acts as a vapor barrier, preventing moisture from entering the building envelope when applied correctly.

The real issue lies in improper installation or using the wrong type of spray foam for specific climate conditions. In hot, humid climates, unvented attics with spray foam on the roof deck require careful planning to prevent condensation issues. Open-cell foam allows some moisture transmission and works better in certain assemblies where drying potential matters.

Building science experts recommend spray foam on roof decks in unvented attics because it brings the roof structure inside the conditioned space. This protects roofing materials from temperature extremes and extends roof life. The key is to use the correct product thickness and ensure the assembly can handle any moisture that may enter.

Myth 3: Spray foam is dangerous to health

Fully cured spray foam is inert and safe. The chemical reaction happens during installation, producing off-gassing that dissipates within 24 to 72 hours in properly ventilated spaces. Reputable installers require homeowners to vacate during application and for a period afterward.

The concern about health risks typically relates to do-it-yourself installations or applications by untrained contractors. Professional installers use appropriate personal protective equipment and ensure proper ventilation throughout the process. The chemicals involved only pose risks during the mixing and application phase.

Ongoing exposure concerns affect installers more than homeowners. Professional crews wear full protective gear, including respirators, during application. Once cured, the plastic material becomes chemically stable and does not off-gas. Testing of cured spray foam consistently shows volatile organic compound levels well below safety thresholds.

Myth 4: Spray foam isn’t environmentally friendly

Spray foam insulation actually reduces environmental impact by lowering energy consumption over the life of a building. While the production process uses petrochemicals, the carbon savings from reduced heating and cooling far outweigh the initial manufacturing footprint. Many spray foam products now use blowing agents with lower global warming potential.

According to data from the Spray Polyurethane Foam Alliance, spray foam insulation can significantly reduce a building’s carbon footprint by decreasing energy use over time. The insulation lasts the life of the structure without needing replacement or maintenance, reducing waste compared to materials that require periodic replacement.

The industry has shifted toward hydrofluoroolefin blowing agents with much lower global warming potential than earlier formulations. These new blowing agents reduce the environmental impact during manufacturing while maintaining performance. Some manufacturers also incorporate recycled content and bio-based materials into their formulations.

The energy savings from spray foam insulation directly reduce greenhouse gas emissions from power plants and home heating systems. A well-insulated home requires less energy to maintain comfortable temperatures, lowering the overall environmental footprint of the building over its lifetime.

Myth 5: DIY spray foam works just as well

Professional spray foam installation requires specialized equipment, proper mixing ratios, and knowledge of substrate preparation. DIY kits exist but lack the expansion control and coverage consistency of professional systems. Improper application can lead to gaps, uneven coverage, and poor performance.

The difference between professional and DIY applications comes down to consistency and coverage. Professional rigs maintain exact temperatures and pressures to ensure proper chemical mixing. DIY kits rely on aerosol pressure and ambient temperature, both of which can vary significantly. This variation affects expansion rate, cell structure, and final R-value.

Professional installers understand how to read the spray pattern and adjust gun technique for different substrates and application conditions. They know when surfaces need preparation or primer to ensure proper adhesion. DIY applications often fail because the substrate wasn’t properly cleaned or prepared, leading to delamination and air gaps.

Table: Professional vs DIY Spray Foam

| Feature | Professional Installation | DIY Kits |

|---|---|---|

| Expansion Control | Precise through temperature and pressure regulation | Limited control, affected by ambient conditions |

| Coverage Consistency | High with trained applicators | Variable, depends on user’s technique |

| Equipment Quality | Commercial-grade rigs with heated hoses | Basic aerosol canisters |

| Yield | Predictable based on calibrated equipment | Often overstated, difficult to estimate accurately |

| Training Required | Extensive certification and hands-on experience | Minimal, basic instructions only |

| Warranty | Available on materials and labor | None beyond basic product warranty |

| R-Value Verification | Tested and verified | Assumed based on theoretical thickness |

Myth 6: Spray foam doesn’t last long

Spray foam insulation lasts as long as the building itself. Unlike fiberglass that settles and loses R-value over time, spray foam maintains its insulating properties indefinitely. The material bonds permanently to the substrate, creating a durable seal that doesn’t degrade under normal conditions.

Buildings insulated with spray foam thirty years ago still perform at original specifications when installed correctly. The foam’s plastic structure resists mold, mildew, and deterioration. UV exposure causes surface degradation over time, but properly installed foam remains protected behind interior or exterior finishes.

The only real risks to spray foam longevity involve physical damage or extreme environmental conditions. Rodents can damage any insulation material if they gain access. Water damage from leaks can affect foam integrity, but closed-cell foam resists water absorption better than most alternatives. Proper installation includes protecting foam from these foreseeable issues.

Thermal expansion and contraction do not significantly affect spray foam performance. The material expands and contracts slightly with temperature changes but maintains its seal and R-value. Unlike fiberglass batts that sag and pull away from framing, spray foam stays bonded to building components.

Myth 7: Spray foam attracts pests

Pests do not find spray foam appealing as a food source or nesting material. Unlike cellulose insulation, which can attract rodents and insects, spray foam offers no nutritional value. Its rigid structure also makes it difficult for pests to tunnel through.

Termites can sometimes use spray foam as a bridge to reach wood framing, but proper building codes require physical termite barriers between foam and soil. This is a construction detail issue, not a flaw in the insulation material itself. Proper installation leaves an inspection gap at the top of foundation walls to allow termite inspections.

Rodents prefer soft materials that they can easily tunnel through for nesting. The density and structure of cured spray foam make it unappealing for this purpose. While determined pests might chew through foam to access other areas, they do not consume the material itself or prefer it over other options.

Carpenter ants and similar pests do not feed on or nest in spray foam. The material provides no food value and offers poor nesting conditions. Pests that do appear in foam-insulated homes typically enter through gaps or openings that proper air sealing would have prevented.

Myth 8: All spray foam is the same

Two main types of spray foam exist: open-cell and closed-cell. Each serves different purposes and performs differently in various applications. Open-cell foam expands more, fills irregular spaces better, and costs less, but has a lower R-value per inch. Closed-cell foam provides a higher R-value, adds structural strength, and acts as a vapor barrier.

Open-cell foam typically has an R-value of 3.5 to 3.8 per inch and expands up to 100 times its liquid volume. This massive expansion helps it fill small cracks and irregular cavities completely. The open cell structure allows some vapor transmission, making it suitable for interior applications in many climates. It remains flexible after curing, accommodating normal building movement.

Closed-cell foam has an R-value of 6.0 to 7.0 per inch and expands about 30 to 40 times its liquid volume. Its density provides structural benefits, actually strengthening the building assembly. The closed cell structure blocks moisture transmission, making it an effective vapor barrier. This characteristic requires careful application planning to avoid trapping moisture where it shouldn’t be.

Choosing between types requires understanding specific project needs, climate conditions, and budget considerations. Neither type is universally better. Each excels in different scenarios. A professional assessment should consider the entire building assembly rather than looking at insulation in isolation.

Bonus Tip: Many projects benefit from using both types strategically. Open-cell works well for interior wall cavities where cost matters more than maximum R-value. Closed-cell serves best on exterior surfaces, roofs, and in areas prone to moisture exposure.

Things to Consider Before Making a Decision

Climate plays a significant role in selecting the right spray foam system. Hot and humid regions like the Southeast benefit from closed-cell foam’s vapor barrier properties, while mixed climates might work well with open-cell applications in certain assemblies.

The building’s existing condition also matters. Spray foam cannot solve problems with major structural issues, roofing failures, or chronic moisture intrusion. These problems need to be addressed before insulation installation. Foam installed over damp materials can trap moisture and cause more problems than it solves.

HVAC systems may need adjustment after spray foam installation. The reduced heating and cooling load often means existing equipment now operates with excess capacity. While this improves efficiency, severely oversized equipment can shorten the cycle and fail to dehumidify properly. A mechanical load calculation helps determine if modifications are needed.

Climate-Specific Guidance for Florida:

- Use closed-cell foam on roof decks in unvented attics

- Ensure proper HVAC sizing after foam installation

- Address any existing moisture issues before installation

- Verify that the installer understands local building code requirements

- Consider open-cell for interior walls where sound dampening is desired

Regional Climate Considerations:

- Hot-humid: Prioritize closed-cell foam for moisture control, especially on exterior assemblies

- Mixed-humid: Both types have applications depending on assembly; pay attention to vapor drive direction

- Cold: Closed-cell is often preferred for a higher R-value in a limited space and air sealing

- Marine: Closed-cell provides better resistance to salt air corrosion

- Arid: Open-cell works well in many applications since moisture management is less critical

Local building codes may specify requirements for spray foam insulation, particularly regarding ignition barriers and thermal barriers. Foam exposed to living spaces must be covered with an approved material, such as drywall or an intumescent coating. Understanding these requirements before starting a project helps avoid expensive corrections later.

Final Thoughts

Spray foam insulation offers superior performance when installed by trained professionals who understand building science principles. The myths surrounding this material often stem from poor installations rather than inherent problems with the product itself. Evaluating specific project needs, climate conditions, and budget constraints leads to better decisions than dismissing spray foam based on misconceptions.

Consider the entire building assembly and long-term operating costs rather than focusing only on the initial price. A professional assessment helps determine whether spray foam makes sense for your specific situation and which type would perform best.

Get Professional Insulation Guidance

For personalized guidance on insulation options, Prestige Insulation Solutions provides expert assessments and professional installation. Contact the team at [email protected] or call (850) 429-4969 to discuss specific needs and get answers from experienced professionals who understand local climate requirements.

FAQS

Is spray foam insulation worth the extra cost?

The higher initial cost typically pays for itself through energy savings within five to seven years. Added benefits include better air sealing, moisture control, improved indoor air quality, and the ability to downsize HVAC equipment.

How long does spray foam installation take?

Most residential projects are completed in one to two days, depending on the scope. The curing process requires 24 to 72 hours before the space can be reoccupied, so plan for temporary displacement during this period.

Can spray foam be installed over existing insulation?

Removing existing insulation before spray foam application provides the best results. Spraying over old insulation can trap moisture, reduce overall performance, and compromise the air sealing benefits that make spray foam effective.

Does spray foam require special maintenance?

Once installed, spray foam requires no maintenance. It does not settle, degrade, or need replacement over the life of the building. The only maintenance consideration involves protecting the material from physical damage during renovations or other work.

Will spray foam make my home too tight?

Properly designed homes include mechanical ventilation regardless of insulation type. Spray foam does make homes tighter, which is actually beneficial for efficiency and comfort. Energy recovery ventilators or similar systems provide fresh air without losing conditioned air.

Sources

- U.S. Department of Energy – Official government resource on insulation types, energy savings, and installation guidelines

- Spray Polyurethane Foam Alliance – Industry trade association providing technical data, environmental impact studies, and best practices for spray foam insulation

- Building Science Corporation – Research-based building science information from industry experts, including studies on insulation performance and moisture management