If you’ve ever felt a draft sneaking through your walls during winter or watched your energy bill climb higher each month, you’re not alone. Homeowners and builders across the country face these issues daily. Spray foam insulation offers a practical solution that seals gaps, blocks air leaks, and keeps temperatures steady. This material expands to fill every crack and crevice, creating a tight barrier that traditional insulation often misses.

Spray foam insulation is a liquid substance that turns into a foam when applied. Contractors spray it into place using specialized equipment, and it hardens quickly to form an effective insulator. Unlike batts or blown-in options, spray foam adheres directly to surfaces and provides both insulation and air sealing in one step. These practical advantages make spray foam increasingly popular among homeowners and builders, delivering real results like better comfort, lower utility costs, and homes that stand up to weather extremes.

Why does this matter? In an era of rising energy prices and stricter building codes, efficient insulation helps cut down on heating and cooling expenses. Data from the U.S. Department of Energy indicates that proper insulation can reduce household energy use by 15% or more. For businesses, it means reducing operational costs and meeting sustainability goals. Spray foam’s ability to improve indoor air quality and resist moisture also prevents costly repairs down the line.

This guide pulls together everything you need to know about spray foam insulation. You’ll start with the basics: what it is and the different types available. From there, explore the key benefits and where it works best in homes and buildings. Learn the installation process step by step, factors that affect performance, and ways to handle common challenges. You’ll also see how to measure returns on your investment and peek at what’s coming next in the field. By the end, you’ll have the knowledge to decide if spray foam fits your project.

Drawing from over two decades of hands-on work installing and evaluating insulation systems, this resource shares practical lessons from real jobsites. Whether you’re a homeowner planning renovations or a contractor seeking reliable options, the information here equips you to make informed choices.

What Is Spray Foam Insulation?

Spray foam insulation starts as two chemicals: polyol resin and isocyanate. When mixed at the nozzle of a spray gun, they react and expand up to 100 times their liquid volume. This expansion fills voids completely, forming a solid barrier. The process happens fast, often curing in seconds, so crews can move quickly without much downtime.

At its heart, spray foam works by trapping tiny air pockets within the foam structure. These pockets resist heat flow, giving the material a high R-value, which measures insulating power. R-value tells you how well something blocks heat; higher numbers mean better performance per inch of thickness.

You might hear spray foam called polyurethane foam because that’s the base chemistry. But not all polyurethane foams suit insulation—only specific formulations designed for building use. The Spray Polyurethane Foam Alliance sets standards to ensure quality and safety in these products.

One big advantage over older methods is its versatility. Spray foam molds to irregular shapes, like around pipes or electrical boxes, where fiberglass batts might leave gaps. This sealing effect stops conditioned air from escaping and outside pollutants from entering, which improves overall efficiency.

Think about a typical attic space with recessed lights and vents. Traditional insulation might sag or compress, creating paths for air movement. Spray foam locks in place and covers those spots seamlessly. Homeowners report feeling the difference right away—rooms stay warmer in cold snaps and cooler during heat waves.

To grasp why spray foam stands out, consider air infiltration. As mentioned earlier, the U.S. Department of Energy estimates that air leaks account for 25-40% of a home’s energy loss. Spray foam addresses this head-on by expanding to block those leaks, often outperforming other materials in blower door tests that measure airtightness.

If you’re new to this, start by assessing your space. Older homes built before modern codes often have more leaks, making spray foam a strong upgrade. New construction benefits too, as builders incorporate it from the start for long-term savings.

Types of Spray Foam Insulation

Spray foam comes in two main varieties: open-cell and closed-cell. Each has unique properties that suit different needs. Understanding the differences helps you pick the right one for your climate, budget, and building type.

Open-Cell Spray Foam

Open-cell spray foam has bubbles that connect, making it softer and more flexible. It expands a lot—up to 100 times—and weighs less, around 0.5 pounds per cubic foot. This type absorbs sound well and allows some vapor to pass through, which can prevent moisture buildup in humid areas.

Installers use open-cell for interior walls or attics where weight isn’t an issue. Its R-value sits at about 3.5 to 4 per inch, solid for many applications. Because it doesn’t form a vapor barrier, pair it with other moisture controls in damp climates.

One real-world example: In a renovated ranch-style home in Florida, open-cell foam filled wall cavities without adding bulk. The result? Quieter rooms and steady temperatures without the risk of trapped humidity leading to mold.

Closed-Cell Spray Foam

Closed-cell foam features sealed bubbles, giving it a rigid, dense structure—about 2 pounds per cubic foot. It expands less, around 30 times, but packs more insulating punch with an R-value of 6 to 7 per inch. This makes it thinner yet effective, ideal for spaces with limited room.

Its closed structure repels water and adds structural strength, acting like a reinforcement in roofs or rim joists. Closed-cell also serves as a thermal, air, and vapor barrier in one, simplifying builds in cold or coastal regions.

Consider a commercial warehouse in the Midwest. Closed-cell spray foam on the roof reduced heat loss by 40%, per on-site energy audits, while handling occasional leaks without damage.

| Type | Density (lbs/ft³) | R-Value per Inch | Key Strengths | Best For |

|---|---|---|---|---|

| Open-Cell | 0.5 | 3.5-4 | Sound dampening, flexible, cost-effective | Interior walls, attics in mild climates |

| Closed-Cell | 2 | 6-7 | High insulation, moisture resistance, structural support | Roofs, exteriors, wet areas |

This table highlights the trade-offs. Open-cell saves money upfront but might need more thickness. Closed-cell costs more but delivers better long-term performance in tough conditions.

Based on these differences, Expert Tip: Before choosing, test a small area. Spray a sample board to see expansion and check how it adheres to your surfaces. This simple step avoids surprises during full installation.

Benefits of Spray Foam Insulation

Spray foam delivers results that go beyond basic warmth. Its design tackles multiple home comfort issues at once, leading to noticeable improvements in daily life.

First, energy savings top the list. By sealing air leaks and providing high R-values, spray foam cuts heating and cooling demands. The U.S. Department of Energy notes that homes with spray foam use up to 50% less energy for HVAC compared to uninsulated ones. Imagine trimming hundreds off your annual bill—that adds up fast.

Second, it boosts comfort. No more cold floors or hot spots; the even barrier keeps temperatures consistent. In summer, it blocks radiant heat from roofs, keeping attics cooler and reducing AC strain.

Third, durability stands out. Once set, spray foam lasts 25-50 years without settling or losing effectiveness, unlike fiberglass that can sag over time. It resists pests like rodents and insects too, protecting your investment.

Moisture control rounds out the advantages. Closed-cell foam’s water resistance prevents rot and mold, crucial in flood-prone or humid zones. A study by Oak Ridge National Laboratory found spray foam walls held up better in humidity tests than traditional setups.

Market data backs this: The spray foam market hit $2.8 billion in 2022, projected to reach $4.5 billion by 2030, driven by demand for energy-efficient builds.

Additionally, spray foam offers noise reduction. Open-cell foam absorbs sound waves, quieting traffic or neighbor chatter in urban settings.

Expert Tip: Pair spray foam with ventilation systems for best air quality. It seals tight, so fresh air intake prevents stuffiness.

Key Takeaways:

- Spray foam saves energy by sealing leaks and insulating effectively.

- It improves comfort, durability, and moisture resistance.

- Long-term benefits include lower bills and fewer repairs.

Common Uses and Applications

Spray foam fits a wide range of projects, from single-family homes to large commercial spaces. Its adaptability makes it a go-to for pros tackling diverse challenges.

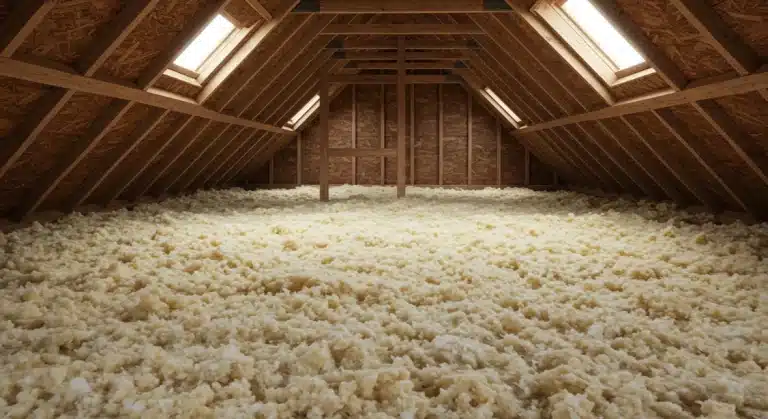

In residential settings, attics top the list. Spray it between rafters to create a continuous layer that stops heat escape. Walls come next—inject it into cavities for seamless coverage, especially in retrofits where accessing every stud bay proves tricky.

For basements and crawl spaces, closed-cell foam shines. It blocks ground moisture and keeps radon or pests at bay. Rim joists, those edges where floors meet walls, often get overlooked but benefit hugely from a quick spray to eliminate drafts.

Commercial uses expand further. Warehouses use it on metal roofs to prevent condensation and energy loss. Schools and offices apply it to walls for quiet, efficient interiors.

Specialty applications include cathedral ceilings or irregular roofs. Foam fills gaps around skylights or dormers without cutting and fitting pieces. In marine environments, like boathouses, its water resistance holds up against splashes.

Take a mid-sized office building in Texas. Installers used open-cell in interior partitions for sound control and closed-cell on the exterior for thermal breaks. Post-install audits showed a 30% drop in cooling costs during peak summer.

Agriculture sees spray foam in barns and silos, insulating against temperature swings that affect livestock or stored goods. Green building projects incorporate it for LEED credits, as it supports energy modeling goals.

Always match the type to the spot. Open-cell suits dry, interior areas; closed-cell handles exteriors or wet zones. This principle applies similarly in residential multi-story settings.

Expert Tip: In multi-story homes, prioritize lower levels first. Ground-floor insulation stabilizes the whole house’s temperature base.

The Installation Process Step by Step

Installing spray foam requires skill and the right gear, but following a clear process ensures success. Here’s how it typically unfolds.

Start with preparation. Clear the area of debris, cover vents or fixtures with plastic, and ensure good ventilation. Check surfaces for cleanliness—dust or grease weakens adhesion. In existing structures, remove old insulation if it’s compressed or contaminated.

Next, set up equipment. Pros use a proportioning unit to mix chemicals, hoses to reach spots, and protective gear like respirators and suits. Temperature matters: Aim for 60-80°F indoors and similar for materials to get proper expansion.

Apply in layers. Begin at the farthest point and work back to avoid getting boxed in. Spray in passes of 2-4 inches, letting each cure before adding more. For walls, fill cavities from bottom to top.

Monitor expansion. Open-cell grows fast; watch for overfill that could bow surfaces. Closed-cell sets denser, so adjust pressure for even coverage.

Finish up with trimming. Use a saw to cut excess flush with framing. Inspect for gaps and touch up as needed. Allow full cure—usually 24 hours—before enclosing with drywall.

Safety first: Follow EPA guidelines on handling isocyanates, which can irritate skin or lungs. Trained crews minimize risks.

A typical single-story home might take 1-2 days. Larger jobs span weeks, but the payoff in efficiency justifies the effort.

Factors Affecting Performance

Performance hinges on several elements, from material quality to site conditions. Get these right, and spray foam delivers peak results.

R-value leads the pack. As noted, open-cell hits 3.5-4 per inch; closed-cell doubles that. But thickness matters—aim for code minimums, like R-38 for attics in northern zones.

Moisture plays a role. Closed-cell repels it, but open-cell needs vapor barriers in wet climates.

Aging affects longevity. Quality foams retain 90% of R-value after 25 years, per lab tests, but UV exposure degrades it if left uncovered.

Application quality counts. Uneven spraying creates weak spots. Blower door tests post-install verify airtightness; aim for under 3 air changes per hour.

Climate influences choice. In hot, humid South, closed-cell prevents condensation. Cold North benefits from its thermal break.

Market stat: 70% of new U.S. homes use advanced insulation like spray foam, up from 40% a decade ago.

| Factor | Impact on Performance | Mitigation Strategy |

|---|---|---|

| Thickness | Higher R-value with more inches | Follow local codes and energy audits |

| Moisture | Reduces effectiveness if unmanaged | Use appropriate type and barriers |

| Application | Gaps lower efficiency | Hire certified installers |

Key Takeaways:

- R-value and thickness determine heat resistance.

- Manage moisture to maintain long-term performance.

- Proper installation ensures full benefits.

Expert Tip: Conduct a thermal imaging scan after install. It reveals hot or cold spots for quick fixes.

Common Challenges and Solutions

No insulation is perfect, and spray foam has hurdles. Knowing them helps you prepare.

Cost ranks high—it’s pricier than batts, running $1-3 per square foot installed. Solution: Calculate ROI. Savings often recoup costs in 3-5 years via lower bills.

Off-gassing concerns arise during cure. Isocyanates release fumes, but modern low-VOC formulas minimize this. Ventilate well and wait 24-72 hours before occupancy.

Shrinkage or voids happen if temps are off. Cold slows expansion, leading to gaps. Train crews on weather adjustments and use heated trailers for materials.

Regulatory issues pop up in fire-prone areas. Some foams need intumescent coatings for code compliance. Check local rules early—the International Building Code outlines requirements.

For DIY attempts, equipment access poses problems. Rentals exist, but pros recommend certification to avoid waste.

In one job, a team faced high humidity causing poor adhesion. They dehumidified the space first, ensuring a solid bond.

Measuring Success and ROI

Track success with metrics that show real impact. Start with energy bills—compare before and after. A 20-30% drop signals good work.

Use audits. Hire an energy rater for blower door and duct tests. These quantify leaks reduced and efficiency gained.

Calculate ROI simply: Divide install cost by annual savings. If $5,000 install saves $1,000 yearly, payback is 5 years. Factor in incentives.

Comfort surveys help too. Ask occupants about drafts or noise; improvements build value.

Long-term, appraise your property. Insulated homes sell faster and for 5-10% more, per real estate data.

Market insight: Energy-efficient retrofits like spray foam qualify for federal tax credits up to $1,200 under the Inflation Reduction Act, as detailed by the IRS.

Future Trends in Spray Foam Insulation

The field evolves with focus on sustainability and tech. Bio-based foams incorporate soy or plant oils, cutting petroleum use by 50% without losing performance.

Smart integrations emerge—foams with embedded sensors monitor moisture or temperature in real time, alerting to issues early.

Variable-rate equipment improves precision, reducing waste. Drones apply foam in hard-to-reach spots like high roofs.

Regulations push greener options; expect more low-GWP blowing agents to replace HFCs, aligning with EPA phase-downs.

By 2030, hybrid foams blending open and closed cells could offer customizable properties for specific jobs.

Putting Your Spray Foam Insulation Strategy into Action

You’ve covered the ground: from types and benefits to installation and trends. Spray foam stands as a reliable choice for energy savings, comfort, and durability. Key points include selecting the right type for your needs, ensuring proper application, and tracking results for ongoing value.

Use this guide as your reference. Start with a home energy audit to pinpoint weak spots. Then, consult local codes and get quotes from certified installers. With these steps, you’ll build a more efficient, comfortable space that lasts.

Need Expert Guidance?

Ready to apply spray foam to your project? Prestige Insulation Solutions offers consultations tailored to your home or business. Reach out at [email protected] or call (850) 429-4969 to discuss options and get a custom plan. Their team brings proven experience to help you achieve top performance without the guesswork.

Sources

- U.S. Department of Energy – Government resource on insulation types, benefits, and energy savings.

- Spray Polyurethane Foam Alliance – Industry association providing standards, training, and safety info for spray foam.

- Oak Ridge National Laboratory – Research on building materials, including moisture performance of insulations.

Frequently Asked Questions About Spray Foam Insulation

Is spray foam insulation safe for homes with allergies?

Yes, once cured, spray foam doesn’t off-gas harmful levels. It seals out dust and pollen, improving air quality. Choose low-VOC products certified by Greenguard for sensitive spaces.

How long does spray foam last?

It endures 25-80 years, depending on type and conditions. Closed-cell holds up best against wear, retaining insulation value over decades.

Can I install spray foam myself?

DIY kits exist for small areas, but full projects need pros. Equipment handling and safety require training to avoid health risks or poor results.

Does spray foam work in hot climates?

Absolutely. Closed-cell blocks radiant heat effectively. In places like Arizona, it keeps interiors cool, slashing AC use by up to 40%.

What about fire safety?

Spray foam meets fire codes when installed correctly. Add thermal barriers like drywall; some formulations self-extinguish.

How does cost compare to other insulation?

It’s higher upfront—$1.50-$3 per sq ft vs. $0.50 for fiberglass—but pays back faster through savings. Expect ROI in 3-7 years.