What is spray foam insulation?

Spray foam insulation, also known as spray polyurethane foam (SPF), is a chemical product created by two materials, isocyanate and polyol resin, which react when mixed to expand up to 30-60 times its liquid volume after it is sprayed into place. This expansion allows it to tightly seal cavities, providing an effective thermal barrier and air seal.

How does spray foam insulation work?

Spray foam insulation works by creating a continuous, airtight seal. When sprayed, it expands to fill cracks, gaps, and voids in walls, attics, crawl spaces, and other areas. This comprehensive seal minimizes air leakage (infiltration and exfiltration), which is a primary cause of energy loss in buildings. By controlling air movement, it helps maintain consistent indoor temperatures and reduces the workload on HVAC systems.

Where can spray foam insulation be used in a home or building?

Spray foam insulation is versatile and can be used in various parts of a home or commercial building, including:

- Attics (roof decks, attic floors)

- Walls (both new construction and existing walls)

- Crawl spaces

- Basements (rim joists, foundation walls)

- Cantilevered floors

- Garages

- Soundproofing interior walls

- Metal buildings

Is spray foam insulation environmentally friendly?

Modern spray foam formulations have improved significantly in terms of environmental impact. Many products now use blowing agents with low Global Warming Potential (GWP). Closed-cell spray foam, in particular, can contribute to significant energy savings over the life of a building, reducing its overall carbon footprint. Some foams are also made with renewable resources like soy or castor oil.

What is R-value and how does it relate to spray foam?

R-value measures a material’s resistance to heat flow; the higher the R-value, the greater the insulating power. Spray foam insulation typically has a high R-value per inch compared to other insulation types. Closed-cell spray foam offers R-values ranging from R-6 to R-7 per inch, while open-cell spray foam provides around R-3.5 to R-3.8 per inch.

What are the main benefits of using spray foam insulation?

The primary benefits include:

- Superior energy efficiency: Reduces heating and cooling costs significantly.

- Excellent air sealing: Minimizes drafts and air leakage.

- Moisture barrier: Closed-cell foam can act as a water vapor retarder.

- Improved indoor air quality: Reduces infiltration of allergens and pollutants.

- Noise reduction: Acts as an effective sound barrier.

- Increased structural integrity: Closed-cell foam can add strength to building assemblies.

- Deters pests: Creates a solid barrier that is difficult for insects and rodents to penetrate.

- Longevity: Does not sag, settle, or degrade over time like some other insulation types.

How does spray foam insulation improve energy efficiency?

Spray foam improves energy efficiency primarily through its exceptional air-sealing capabilities and high R-value. By creating an airtight envelope, it prevents conditioned air from escaping and unconditioned air from entering. This reduces the demand on HVAC systems, leading to lower energy consumption and utility bills.

Can spray foam insulation reduce noise?

Yes, both open-cell and closed-cell spray foam can significantly reduce noise transmission. Open-cell foam, with its softer and more flexible cell structure, is particularly effective at absorbing sound waves, making it an excellent choice for soundproofing interior walls, media rooms, and areas near busy streets.

Does spray foam insulation help prevent mold and mildew?

Spray foam insulation can help prevent mold and mildew growth. Because it creates an air and moisture barrier (especially closed-cell foam), it reduces the potential for condensation to form within walls and other building cavities. Mold requires moisture to grow, so by controlling moisture, spray foam helps create a less hospitable environment for mold and mildew.

Can spray foam insulation improve indoor air quality?

Yes, by sealing cracks and crevices, spray foam insulation significantly reduces the infiltration of outdoor allergens, pollutants, dust, and pests. This can lead to a healthier indoor environment, especially for individuals with allergies or respiratory issues.

Does spray foam add structural integrity to a building?

Closed-cell spray foam, due to its dense and rigid nature, can add significant racking strength to wall assemblies and roof structures. When it cures, it adheres strongly to surfaces and can help to reinforce the building envelope. Open-cell foam does not offer the same structural benefits.

What are the different types of spray foam insulation?

The two main types of spray foam insulation are:

- Open-cell spray foam: Has a softer, more flexible texture as its cells are not fully encapsulated.

- Closed-cell spray foam: Is denser and more rigid, with cells that are completely closed and filled with a gas that enhances its insulating properties.

What is open-cell spray foam?

Open-cell spray foam has a lower density (typically around 0.5 pounds per cubic foot) and a sponge-like appearance. Its cells are intentionally left open, which makes it permeable to water vapor. It expands significantly upon application, making it good for filling large cavities and hard-to-reach areas. It’s an excellent air barrier and sound insulator.

What is closed-cell spray foam?

Closed-cell spray foam has a higher density (typically around 2.0 pounds per cubic foot) and a rigid texture. Its cells are closed and packed tightly together, filled with a special blowing agent that provides a high R-value. It acts as an air barrier, a water vapor retarder, and adds structural rigidity.

What are the differences between open-cell and closed-cell spray foam?

Key differences include:

- R-value: Closed-cell has a higher R-value per inch (R-6 to R-7) than open-cell (R-3.5 to R-3.8).

- Moisture Permeability: Closed-cell is water-resistant and acts as a vapor retarder. Open-cell is vapor permeable.

- Density & Rigidity: Closed-cell is dense and rigid; open-cell is light and flexible.

- Expansion: Open-cell expands more than closed-cell.

- Cost: Open-cell is generally less expensive per unit of R-value than closed-cell foam, but more material might be needed to achieve the same R-value.

- Structural Strength: Closed-cell adds structural strength; open-cell does not significantly.

Which type of spray foam is better for my project?

The best type depends on the specific application, budget, and climate:

- Open-cell is often used for interior walls (sound deadening), attic rooflines (in some climates), and areas where vapor permeability is desired. It’s generally more cost-effective for filling large cavities.

- Closed-cell is ideal for areas requiring high R-value in limited space, locations prone to moisture (basements, crawl spaces), and when structural reinforcement is beneficial. It’s also preferred in colder climates or for exterior applications.

How is spray foam insulation installed?

Professionally trained installers apply spray foam using specialized equipment. The two components (isocyanate and polyol resin) are heated and pumped from a truck or trailer through heated hoses to a mixing gun. When sprayed onto a surface, the components react and expand to create the foam insulation. It adheres directly to the substrate.

How long does the spray foam installation process take?

The duration depends on the size and complexity of the project. A typical residential attic or crawl space might take a few hours to a full day. Larger projects or whole-house applications can take several days.

Do I need to prepare my home before spray foam installation?

Yes, some preparation is usually required:

- Clear the work area of personal belongings and furniture.

- Ensure easy access to the areas being insulated.

- Address any moisture issues or leaks before installation.

- Cover items that cannot be removed to protect them from overspray. Your insulation contractor will provide specific preparation guidelines.

Can spray foam be installed in an existing home?

Yes, spray foam can be installed in existing homes, often as part of a renovation or energy upgrade. It can be applied to attics, crawl spaces, rim joists, and sometimes walls (though wall applications in existing homes can be more complex).

Can I install spray foam insulation myself (DIY)?

While DIY spray foam kits are available for small projects, larger applications should be handled by professional installers. Spray foam installation involves handling chemicals, requires specialized equipment, and precise application techniques to ensure safety and effectiveness. Incorrect installation can lead to poor performance, off-gassing issues, or even damage.

What is the curing time for spray foam insulation?

Spray foam typically becomes tack-free within minutes of application. However, full curing and the time before re-entry into the space can vary depending on the product, ventilation, and environmental conditions. Generally, it’s recommended to stay out of the immediate spray area for 24 hours, but your installer will provide specific guidance.

Is there an odor associated with spray foam installation?

There can be a distinct odor during and shortly after the application process. This odor typically dissipates as the foam cures. Proper ventilation is crucial during and after installation. Most modern foams are designed to be low-odor once fully cured.

How much does spray foam insulation cost?

The cost of spray foam insulation varies based on several factors, including the type of foam (open-cell or closed-cell), the thickness required, the total square footage, the complexity of the job (accessibility, preparation needed), and regional labor rates. Closed-cell foam is generally more expensive than open-cell foam.

What factors affect the cost of spray foam insulation?

- Type of foam: Closed-cell is more expensive per board foot than open-cell.

- Thickness of application: Higher R-value requirements mean thicker foam and higher cost.

- Project size: Larger areas may have a lower per-square-foot cost but a higher overall cost.

- Accessibility: Difficult-to-reach areas may increase labor costs.

- Preparation needed: Extensive prep work can add to the cost.

- Location: Labor rates and material costs can vary by region.

How much can I save on energy bills with spray foam insulation?

Energy savings can be substantial, often ranging from 20% to 50% or more, depending on the initial condition of the home, the extent of the spray foam application, climate, and lifestyle. The air-sealing properties of spray foam are a major contributor to these savings.

Are there any tax credits or rebates for installing spray foam insulation?

Potentially, yes. Various federal, state, or local utility programs may offer tax credits, rebates, or incentives for energy-efficient home improvements, including insulation upgrades. It’s best to check with a tax advisor, your local utility company, or resources like the Database of State Incentives for Renewables & Efficiency (DSIRE).

Is spray foam insulation safe?

When installed correctly by trained professionals and allowed to cure properly, spray foam insulation is considered safe. The chemicals involved in the application require careful handling and safety precautions, including respiratory protection and full-body suits for installers. Homeowners should typically vacate the premises during application and for a specified period afterward (usually 24 hours).

Are there any health concerns associated with spray foam insulation?

The primary health concerns are related to exposure to the chemical components during application and before full curing. Isocyanates can cause respiratory irritation or sensitization. Once cured, spray foam is inert and does not typically off-gas harmful levels of chemicals. Choosing a reputable installer who follows safety protocols is crucial.

Do I need to vacate my home during spray foam installation?

Yes, it is generally recommended and often required for occupants (and pets) to vacate the home during the spraying process and for a period afterward, typically 24 hours, to allow the foam to cure fully and for the area to be ventilated.

What safety precautions are taken during installation?

Professional installers use:

- Personal Protective Equipment (PPE) including respirators, full-body suits, gloves, and eye protection.

- Ventilation systems to control fumes and overspray.

- Containment measures to protect non-target areas. They are also trained in safe handling of the chemical components.

How long does spray foam insulation last?

Spray foam insulation is very durable and can last for the lifetime of the building if installed correctly and not subjected to damage. It does not sag, settle, or decompose like some other insulation materials.

Does spray foam insulation require any maintenance?

Generally, no. Once installed and cured, spray foam insulation is stable and requires no ongoing maintenance. It’s important to ensure it’s not damaged by pests (though it deters them) or by subsequent construction or renovation work.

Does spray foam insulation deteriorate over time?

No, properly installed spray foam does not significantly deteriorate, shrink, or settle over time. Its thermal and air-sealing properties remain consistent throughout its lifespan.

How does spray foam insulation compare to fiberglass insulation?

- R-value: Spray foam (especially closed-cell) has a higher R-value per inch.

- Air Sealing: Spray foam is an air barrier; fiberglass is not and allows air to pass through it.

- Moisture Resistance: Closed-cell spray foam is moisture resistant; fiberglass can absorb moisture, which reduces its R-value and can lead to mold.

- Cost: Spray foam is generally more expensive upfront than fiberglass.

- Installation: Spray foam requires professional installation; fiberglass can be DIY.

How does spray foam insulation compare to cellulose insulation?

- R-value: Spray foam typically has a higher R-value per inch than cellulose.

- Air Sealing: Spray foam provides a better air seal. While dense-packed cellulose can reduce air leakage, it’s not a true air barrier like foam.

- Moisture Resistance: Closed-cell spray foam is moisture resistant. Cellulose is treated to resist moisture but can still absorb it if exposed to significant amounts.

- Installation: Both typically require professional installation for best results, though loose-fill cellulose can be a DIY project.

- Cost: Spray foam is generally more expensive.

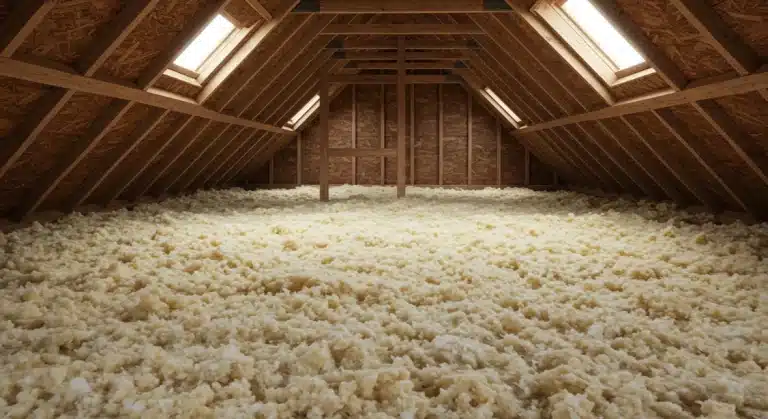

Can spray foam be used in attics?

Yes, spray foam is highly effective in attics. It can be applied to the underside of the roof deck (creating an unvented or conditioned attic) or to the attic floor (in a traditional vented attic). Applying it to the roof deck can help keep the attic cooler in summer and warmer in winter, protecting HVAC equipment and ductwork located there.

Is spray foam suitable for crawl spaces?

Yes, closed-cell spray foam is an excellent choice for crawl spaces. It seals out moisture from the ground, prevents air leakage, and insulates the floor above, making the home more comfortable and energy-efficient. It also helps deter pests.

Can spray foam be used on metal buildings?

Absolutely. Spray foam adheres well to metal surfaces and is commonly used to insulate metal buildings, agricultural structures, and warehouses. It helps control condensation, provides excellent thermal insulation, and can add rigidity to the structure.

Can spray foam be used to insulate basements?

Yes, closed-cell spray foam is ideal for insulating basement walls (both interior and exterior if accessible during construction) and rim joists. Its moisture resistance is a key benefit in potentially damp basement environments.

For specific advice on your project or to get a quote, you can contact:

Prestige Insulation Solutions

(850) 429-4969

[email protected]