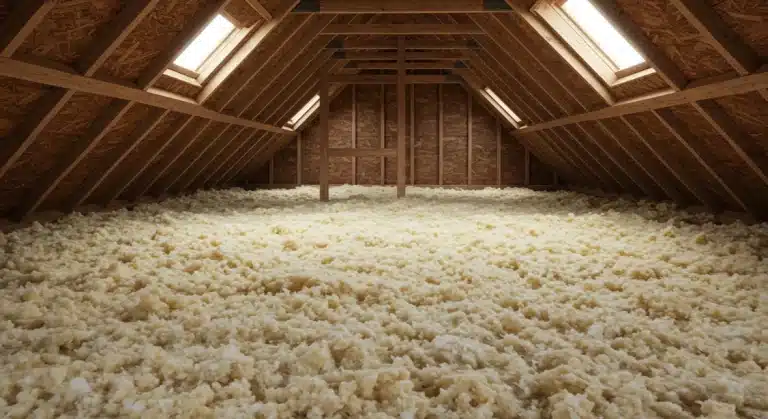

Spray foam insulation expands quickly and fills spaces around electrical wires and pipes, creating a tight seal that boosts energy efficiency. The foam hardens in place, encasing these elements without damaging them if installers follow proper steps. This process prevents air leaks and adds thermal protection directly to the wires and pipes.

Homeowners often worry about safety during this step, but careful preparation keeps everything in check. Drawing on hands-on knowledge from insulation projects across various homes, this article breaks down the full picture, from prep work to long-term outcomes. At Prestige Insulation Solutions, our years of field experience ensure reliable explanations.

How Preparation Protects Wires and Pipes

Before any foam goes down, crews map out the locations of wires and pipes. They use tools like stud finders and thermal imaging to spot hidden lines. This step avoids surprises during application.

For electrical wires, electricians often label junctions and ensure no live circuits interfere. Pipes get checked for leaks or weak spots first. In humid areas like Florida, extra attention goes to moisture-prone pipes to prevent future issues.

Bonus Tip: Always schedule a walkthrough with qualified pros to confirm all utilities are marked. This simple check can save headaches later.

The Step-by-Step Application Process

Spray foam insulation starts as a liquid mix that reacts and expands on contact with air. Installers apply it in layers, starting from the farthest points in the space. The foam builds up around obstacles like wires and pipes, conforming to their shapes.

Open-cell foam, which is softer and more flexible, wraps gently around delicate wires. Closed-cell foam, denser and rigid, provides stronger barrier but requires precise control to avoid pressure on pipes. The process takes hours, depending on the area size.

Market data shows spray foam cuts energy use by up to 50% in homes, per a U.S. Department of Energy report. This efficiency comes partly from how well it seals around utilities.

Building on this application technique, let’s examine the specific impacts on electrical wires.

Impacts on Electrical Wires

When foam covers wires, it acts as an insulator, keeping heat from building up in walls. Wires stay cool and run safely, as the foam doesn’t conduct electricity. However, poor prep can trap heat if airflow gets blocked entirely.

In practice, installers leave small gaps or use baffles near outlets and switches for ventilation. This setup follows codes from the National Electrical Code, ensuring wires handle loads without risk.

A study by the Spray Polyurethane Foam Alliance notes that properly applied foam enhances wire safety by reducing moisture exposure. Over 70% of insulation jobs involve such integrations without incidents.

Bonus Tip: Test circuits after application to confirm no disruptions. Quick voltage checks catch rare issues early.

| Foam Type | Effect on Wires | Key Benefit | Potential Drawback |

|---|---|---|---|

| Open-Cell | Flexible coverage, low density | Allows minor movement, breathable | Less rigid protection |

| Closed-Cell | Rigid seal, high density | Strong moisture barrier | Needs careful application to avoid compression |

Effects on Plumbing Pipes

Pipes get a similar treatment, with foam providing insulation against temperature swings. Hot water lines stay warm longer, and cold lines resist sweating in damp climates. The expansion fills gaps without squeezing the pipes if done right.

In colder regions, this prevents freezing, but in hot spots like the Southeast, it blocks condensation. Installers avoid direct foam contact on PVC pipes by using sleeves, as high expansion could stress joints.

Data from the Building Science Corporation indicates spray foam reduces pipe heat loss by 40%, based on field tests in residential settings.

Risks and Ways to Avoid Problems

One main risk involves over-expansion pinching wires or pipes, leading to cracks or shorts. Moisture trapped under foam can also cause corrosion over time. Dust or debris from old walls might react poorly with the chemicals.

To dodge these, teams wear protective gear and ventilate the area well. They apply foam in controlled amounts, monitoring thickness with gauges. Post-job inspections check for even coverage.

Regional note: In Florida’s humid weather, crews prioritize quick curing foams to limit moisture intake during application.

Bonus Tip: Choose contractors certified by groups like the SPFA for lower risk rates. Their training covers these exact scenarios.

Things to Consider Before Making a Decision

With these risks in mind, homeowners should assess the home’s age and wiring condition first. Older homes with knob-and-tube wiring may not suit full foam coverage. Check local building codes for insulation thickness limits near utilities.

Budget for potential electrician visits, as some jobs require their input. Think about long-term savings on energy bills versus upfront costs. Evaluate if the space needs vapor barriers, especially in mixed climates.

Weigh environmental factors, like foam’s R-value against other insulators. Finally, review contractor credentials to ensure they handle utilities safely.

Common Questions

Does Spray Foam Insulation Affect Home Insurance?

Many wonder if foam affects home insurance. It usually doesn’t, but adding insulation can lower premiums through energy efficiency discounts.

Can Spray Foam Insulation Be Removed if There’s a Problem?

Others ask about removal if issues arise. Foam sticks tight, so cutting it out demands care to avoid structure damage.

Key Takeaways

Spray foam safely encases wires and pipes, improving insulation without harm through smart prep and application. Risks stay low with experienced handling. Evaluate your home’s specifics, like climate and structure, to decide if it fits your needs. Consider consulting experts to match it to long-term energy goals.

Ready to Learn More

For advice on spray foam in your home, reach out to Prestige Insulation Solutions at (850) 429-4969 or [email protected]. Discuss your setup to get tailored insights on safe application around utilities. This step ensures the best results for efficiency and safety. (72 words)

Sources

- U.S. Department of Energy – Government resource on insulation types and energy savings, including spray foam benefits.

- Spray Polyurethane Foam Alliance – Industry group providing standards and research on safe foam applications with utilities.

- Building Science Corporation – Technical site with studies on building materials, covering foam’s impact on plumbing and electrical systems.

Frequently Asked Questions

Can Spray Foam Cause Wires to Overheat?

No, when installed correctly, foam insulates wires and prevents overheating. It blocks external heat sources and maintains stable temperatures. Always confirm with a pro for your setup.

Does Foam Damage Plastic Pipes?

Direct contact can stress plastic, but sleeves and proper techniques protect them. Metal pipes handle it fine with no added measures needed.

How Long Does the Foam Take to Set Around Utilities?

It expands and hardens in minutes, but full cure takes 24 hours. Avoid using affected areas until then to let it settle.

Is Special Equipment Needed for Pipes and Wires?

Yes, detection tools and mixing kits ensure precision. Standard sprayers work, but pros use extras for tight spots.

What If a Pipe Leaks After Foam Goes On?

Access becomes tough, so fix leaks before application. If one occurs later, infrared cameras help locate it for targeted repairs.