Blown-in insulation is a highly effective method for preventing cold floors during the winter. When installed correctly in areas such as a crawl space or the ceiling of an unheated basement, it establishes a thermal barrier. This barrier effectively stops cold air from the ground from infiltrating the living space, which is a primary reason for uncomfortably cold floors. By managing this air movement and minimizing heat transfer, blown-in insulation helps maintain the floor’s surface temperature at a level much closer to your home’s indoor temperature.

This article will delve into how blown-in insulation combats cold floors, compare the various materials available, and detail important factors to consider before you begin the installation process. The information is grounded in extensive field experience in residential insulation, providing practical advice for homeowners seeking a solution to this prevalent winter issue.

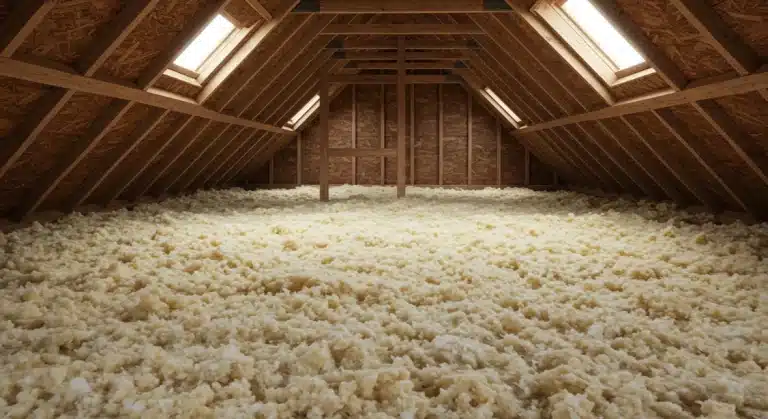

How Blown-In Insulation Fights Cold Floors

Cold floors are typically a symptom of what is occurring underneath them, rather than an issue with the flooring material itself. In houses with basements or crawl spaces, the floor of the main living area is directly exposed to the cold, unconditioned air below. Since heat naturally moves from warmer to cooler areas, the warmth from your heated rooms is continuously drawn down through the floorboards.

Blown-in insulation addresses this by filling the cavities between your floor joists, which creates a dense, continuous layer that resists this heat transfer.

- It Halts Airflow: Cold air from below can seep through small cracks and gaps in the subfloor. Blown-in insulation, especially cellulose, is adept at filling these irregular spaces, which significantly reduces drafts and convective heat loss.

- It Slows Conduction: Heat also moves through solid materials in a process known as conduction. The millions of tiny air pockets trapped within the insulation material act as poor conductors of heat, effectively slowing the rate at which warmth escapes through the floor structure.

A report from the U.S. Department of Energy highlights that insulating floors over unheated spaces is a crucial strategy for enhancing home comfort and efficiency. It is estimated that homeowners can save an average of 15% on heating and cooling costs by air sealing their homes and adding insulation to areas like attics, floors, and crawl spaces.

Bonus Tip: The rim joist, the wooden component that sits on top of the foundation wall and runs along the perimeter of the floor framing, is a significant source of heat loss. Sealing and insulating this area is as important as insulating the main floor cavities.

Comparing Blown-In Insulation Materials for Floors

Selecting the right material is vital for achieving the best results. The three primary types of blown-in insulation each possess unique properties and thermal resistance, or R-values. According to the International Association of Certified Home Inspectors (InterNACHI®), the R-value per inch can differ significantly between materials like cellulose, fiberglass, and rock wool, making each suitable for different applications.

| Insulation Type | Material Composition | Avg. R-Value per Inch | Key Characteristics |

|---|---|---|---|

| Cellulose | Recycled paper, treated with borates | 3.2 – 3.8 | Excellent air sealing, good sound dampening, Class 1 fire rating. |

| Fiberglass | Spun glass fibers | 2.2 – 2.7 | Naturally moisture and mold-resistant, non-combustible. |

| Rock Wool | Basalt rock and slag | 3.0 – 3.3 | Superior fire resistance, excellent soundproofing, and moisture-repellent. |

Cellulose is frequently the preferred option for insulating floors due to its density, which allows it to conform to every gap and provide superior air sealing. However, for crawl spaces with potential moisture problems, fiberglass or rock wool may be better choices because their inorganic nature makes them less prone to mold growth.

Factors to Consider Before Making a Decision

Before you proceed with an installation, several factors must be assessed to ensure the project is successful and addresses the root cause of your cold floors.

Crawl Space or Basement Condition

The environment beneath your floors will determine the most effective approach. Is it damp or susceptible to flooding? A damp crawl space must be addressed before any insulation is installed. This might entail adding a vapor barrier to the ground to manage moisture evaporation. Neglecting this step can lead to trapped moisture, which could damage your home’s structure and render the insulation ineffective.

Climate and Required R-Value

Your geographical location influences the recommended level of insulation, or R-value. Homes in colder climates require more insulation to effectively combat heat loss. According to guidelines from ENERGY STAR, homes in the southern United States should aim for an R-value of R-19 to R-25 for floors, while those in the north may need R-25 to R-30 for optimal performance.

Existing Obstructions

The space between floor joists often contains wiring, plumbing pipes, and HVAC ductwork. A professional installation ensures that the insulation is carefully packed around these obstructions without compressing them, which could diminish their effectiveness or cause damage.

Bonus Tip: Before insulating, take the time to seal any gaps or penetrations in the subfloor where pipes and wires pass through. A can of spray foam can make a significant difference in stopping small air leaks that insulation alone might not completely block.

A Warmer Home Starts from the Ground Up

Blown-in insulation provides a reliable and long-lasting solution to the problem of cold floors. By creating a solid thermal envelope between your living space and the unconditioned area below, it keeps your home more comfortable and can lead to lower energy bills. The key is to select the right material for your specific situation and ensure the space is properly prepared before the installation begins. When done correctly, you will feel the difference under your feet all winter long.

Get a Professional Assessment

Understanding the unique conditions of your home is the first step toward a permanent solution for cold floors. For a detailed evaluation and personalized recommendation, you can contact Prestige Insulation Solutions LLC. To discuss your project, call (850) 429-4969 or send an email to [email protected]. Seeking expert advice ensures you make an informed decision that will provide comfort and value for years to come.

Sources

- U.S. Department of Energy: Provides official government information on home insulation strategies and potential energy savings.

- ENERGY STAR: Offers recommendations for insulation levels (R-values) based on climate zones across the United States.

- International Association of Certified Home Inspectors (InterNACHI®️): An educational resource providing detailed information and R-value specifications for common insulation materials.

Frequently Asked Questions About Blown-In Insulation and Floors

Here are answers to some common questions homeowners have about using blown-in insulation for floors.

What R-value is best for floors?

For most climates in the U.S., an R-value between R-19 and R-30 is recommended for floors over unconditioned spaces. The precise amount depends on your local climate zone. A higher R-value provides greater thermal resistance and better performance in colder regions.

Will insulating my crawl space cause moisture problems?

If done correctly, it should not. A proper installation includes evaluating the current moisture situation and, if needed, installing a vapor barrier on the ground. The aim is to control moisture at its source, not to trap it within the floor system.

How long does blown-in insulation last under a floor?

When installed correctly in a dry, protected space like a floor cavity, blown-in insulation can last for the lifetime of the home. Materials such as fiberglass and rock wool do not settle or degrade over time. Cellulose may settle slightly over many years, but this is minimal when properly dense-packed.

Can I insulate the floors of an upper story?

Yes, and it is an excellent way to reduce noise transfer between floors. While it will not have a significant thermal impact unless the space below is unheated, the sound-dampening qualities of cellulose and rock wool can make a noticeable difference in a home’s acoustics.