Is your home struggling to stay comfortable? Do you notice drastic temperature swings between rooms, or are your energy bills consistently higher than they should be? These are common problems, and the solution is often hidden from view, right above your head or inside your walls. An underperforming thermal envelope, the barrier between your conditioned living space and the outside world, is frequently the culprit. This is where blown-in insulation becomes one of the most effective solutions for creating a more comfortable, energy-efficient home.

This guide is designed to be your complete resource on the subject. Drawing from years of hands-on experience, Prestige Insulation Solutions LLC has put together this page to walk you through everything you need to know. We will explore what blown-in insulation is, the different materials available, and where it works best. You’ll learn about the installation process, how to understand performance metrics like R-value, and what kind of return on investment you can expect. Think of this as the definitive manual for anyone considering this upgrade for their property.

Here’s what you’ll find inside:

- A Foundational Look at Blown-In Insulation: We’ll start with the basics, explaining the concept and why it’s a go-to choice for new and existing homes.

- The Three Main Types: A detailed breakdown of fiberglass, cellulose, and mineral wool, including their pros and cons.

- Key Applications: Discover the most effective places to use blown-in insulation, from attics to tricky wall cavities.

- Benefits Beyond Temperature: Learn about energy savings, sound reduction, fire resistance, and more.

- The Installation Process Demystified: A step-by-step look at what happens on installation day.

- Understanding R-Value: We’ll make sense of the most important insulation performance metric.

- Costs, Challenges, and Long-Term Value: A realistic look at the investment and how to handle common issues.

By the end of this guide, you’ll have a clear and complete understanding of how blown-in insulation works and whether it’s the right choice for your home.

What Is Blown-In Insulation? A Foundational Look

Blown-in insulation, also known as loose-fill insulation, is exactly what it sounds like. It’s a type of thermal insulation material made of small particles of fiber, foam, or other materials. Unlike traditional batt insulation that comes in pre-cut rolls, this material is installed using a specialized blowing machine. The machine agitates the material to fluff it up and then uses a long, flexible hose to blow it into the desired space.

The real advantage of this method is its ability to create a seamless, custom-fit blanket of insulation. It easily fills nooks, crannies, and irregular spaces, covering joists and getting around obstructions like pipes, wires, and cross-bracing. This comprehensive coverage is crucial because it directly addresses air leakage. A report from the U.S. Department of Energy highlights that air leakage can account for a significant portion of a home’s heating and cooling costs, which is a problem blown-in insulation directly addresses. By creating a tight seal, it helps stop the movement of air, which is a primary driver of energy loss.

This method is particularly well-suited for two main applications: open attics and enclosed existing wall cavities. In attics, it’s used to create a deep, uniform layer over the attic floor. For walls, a technique called “dense-packing” is used, where the material is blown into the wall cavity under pressure to ensure it fills the entire space without settling over time.

The Big Three: Types of Blown-In Insulation

When you choose blown-in insulation, you’re not just choosing a method; you’re also choosing a material. There are three primary types on the market today, each with its own unique set of properties, benefits, and considerations.

Blown-In Fiberglass

This is one of the most common types of insulation. It’s made from molten glass that is spun into fine fibers. Modern blown-in fiberglass is typically made from a high percentage of recycled glass content, making it a more sustainable choice than older versions.

- Pros: It’s naturally non-combustible, lightweight, and resistant to moisture and mold growth. Because it’s an inorganic material, it doesn’t support pests. It also doesn’t settle much over time when installed correctly in an open attic.

- Cons: While it stops heat transfer through conduction, it can be less effective at stopping airflow if not installed densely enough. Some people experience skin irritation during installation if proper protective gear isn’t used.

Blown-In Cellulose

Cellulose insulation is made primarily from recycled paper products, like newspapers and cardboard. The paper is shredded into small pieces and treated with non-toxic borates to make it fire-retardant and resistant to pests and mold.

- Pros: Cellulose has excellent thermal performance and is particularly good at stopping air movement. Its production requires less energy than other insulation types, giving it a lower embodied carbon footprint. The borate treatment gives it the highest fire resistance rating (Class 1).

- Cons: Because it’s a plant-based material, it is more susceptible to absorbing moisture if a leak occurs. If it becomes saturated, it can compress and lose some of its R-value. Proper air sealing and vapor barriers are especially important when using cellulose.

Mineral Wool (Rock Wool)

Also known as rock wool or slag wool, mineral wool is created by melting basalt rock and steel slag and spinning them into a fiber-like structure. It’s available in both batt and loose-fill form.

- Pros: Mineral wool is prized for its exceptional fire resistance; it’s non-combustible and can withstand temperatures above 1,000°F. It also has excellent sound-dampening qualities, making it a great choice for reducing noise between floors or from the outside. Like fiberglass, it’s moisture-resistant and won’t support mold.

- Cons: It is typically the most expensive of the three options. It’s also denser and heavier, which can be a consideration for certain applications.

Material Comparison at a Glance

| Feature | Blown-In Fiberglass | Blown-In Cellulose | Mineral Wool |

|---|---|---|---|

| Primary Material | Spun glass fibers | Recycled paper/wood fiber | Volcanic rock & slag |

| R-Value per Inch | ~2.2 – 2.9 | ~3.2 – 3.8 | ~3.0 – 3.3 |

| Fire Resistance | High (non-combustible) | Very High (treated) | Exceptional |

| Moisture Resistance | High | Low (can absorb water) | High |

| Sound Dampening | Good | Very Good | Excellent |

| Cost | $ | $$ | $$$ |

Key Takeaways The key takeaway is that choosing the right material depends on your priorities.

- For a cost-effective and moisture-resistant solution, fiberglass is a solid choice.

- For superior air-sealing and a greener profile, cellulose is an excellent performer.

- For maximum fire safety and soundproofing, mineral wool is the premium option. You should discuss your specific needs, budget, and home conditions with a professional to determine the best fit.

Where Can You Use Blown-In Insulation? Key Applications

The versatility of blown-in insulation allows it to be used in several areas of a home where other insulation types might be difficult to install.

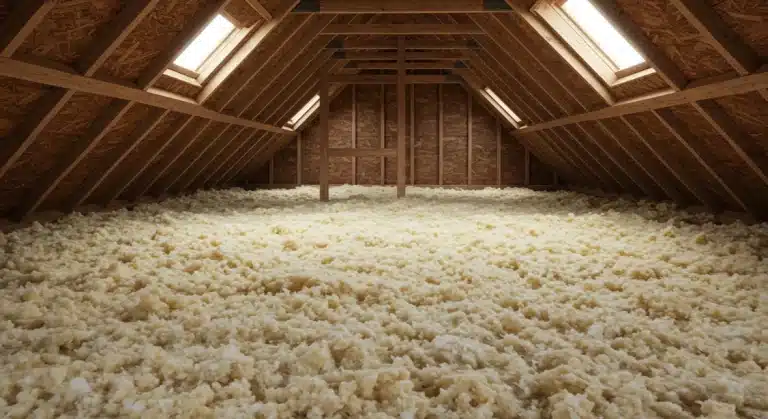

Attics: The Most Common Application

Attics are the number one spot for blown-in insulation. The process is fast and efficient. An installer can blow a thick, continuous blanket of insulation over the entire attic floor, easily covering joists and filling gaps around vents, pipes, and wiring. This creates a superior thermal break compared to traditional batts, which often leave gaps when cut and fit around obstacles. Upgrading attic insulation is often one of the most impactful energy efficiency improvements a homeowner can make.

Expert Tip: Before blowing in new insulation, it’s a good idea to air seal the attic floor. This means finding and sealing all the small cracks and openings around light fixtures, plumbing stacks, and electrical wires that lead into the living space below. This simple step can dramatically reduce air leakage and boost the performance of your new insulation.

Existing Walls (Dense-Pack)

What if your home was built with little to no insulation in the walls? Tearing out drywall to install batts is a messy and expensive project. This is where dense-pack insulation shines. Installers can drill small, strategic holes in the exterior or interior walls, insert the hose, and blow the insulation into the empty cavity under high pressure. The pressure ensures the material compacts and fills the entire space, preventing it from settling later. Once done, the holes are plugged and patched, leaving minimal trace of the work. It’s a minimally invasive way to dramatically improve the comfort and efficiency of existing walls.

Other Applications

- Crawl Spaces & Floors: Blown-in insulation can be used between floor joists above unconditioned crawl spaces or basements. It’s often held in place with a vapor-permeable netting.

- Cathedral Ceilings: The dense-pack method can also be used for vaulted or cathedral ceilings that don’t have traditional attic space, provided there’s a cavity to fill.

The Benefits: More Than Just Temperature Control

While the main goal of insulation is to keep your home warmer in the winter and cooler in the summer, the advantages of a properly insulated house extend much further.

- Significant Energy Savings: This is the most celebrated benefit. A well-insulated attic can save homeowners an average of 15% on heating and cooling costs, according to the U.S. Environmental Protection Agency’s ENERGY STAR program. By reducing the workload on your HVAC system, you lower your utility bills month after month.

- Improved Home Comfort: A continuous blanket of insulation reduces drafts and eliminates hot and cold spots. Your home will maintain a more consistent, comfortable temperature year-round, making your living spaces more enjoyable.

- Excellent Sound Dampening: Blown-in materials, especially cellulose and mineral wool, are fantastic at absorbing sound. This can reduce noise from outside (like traffic) and also quiet sounds traveling between different rooms and floors of your house.

- Enhanced Fire Safety: Both mineral wool and treated cellulose have excellent fire-resistant properties. They don’t burn easily and can help slow the spread of flames in the event of a fire, potentially giving your family more time to exit safely.

- Environmental Impact: Cellulose is made from up to 85% recycled material, diverting tons of paper from landfills. Fiberglass also contains a significant amount of recycled glass. By reducing your home’s energy consumption, you also shrink its carbon footprint, aligning your home with the growing demand for sustainable building practices.

The Installation Process: What to Expect

A professional blown-in insulation job is a well-coordinated process that is typically completed in less than a day. Here’s a general overview of the steps involved.

- Preparation: The crew will first inspect the area to be insulated. In an attic, this involves checking for any existing issues like moisture or pest problems. They will install soffit baffles to ensure ventilation pathways remain clear and protect things like recessed lights or mechanical equipment from being covered. For walls, they’ll locate the stud bays to plan the drilling pattern.

- Setup: The blowing machine is usually mounted on a truck or trailer that stays outside your home. Large bags of insulation material are fed into the machine’s hopper. A long, flexible hose is run from the machine into your home, leading to the attic or the specific wall being insulated.

- Blowing the Insulation: One technician feeds material into the machine while another directs the hose inside, applying the insulation. In an attic, they will move methodically across the space, blowing the material to a specific, calculated depth to achieve the target R-value. For dense-packing walls, they work one cavity at a time until it’s completely filled.

- Cleanup and Finishing: After the blowing is complete, the crew will clean up any dust or stray material. For wall insulation, the access holes are plugged with durable plugs, and if the work was done from the inside, they are often patched with a first coat of spackle, ready for you to sand and paint.

- Expert Tip: Ask the installers to put up an attic ruler. This is a simple marked ruler stapled to a roof truss that shows the depth of the insulation. It’s an easy way for you to verify that the correct amount was installed and to check for any settling years down the road.

Understanding R-Value and Blown-In Insulation

You can’t talk about insulation without talking about R-value. But what does it actually mean?

R-value is a measure of thermal resistance. In simple terms, it indicates how well insulation can resist the flow of heat. The higher the R-value, the better the insulating performance. The amount of R-value you need depends on your climate zone, the part of the house you’re insulating, and local building codes.

The U.S. Department of Energy provides recommendations for insulation levels across the country. For example, in warmer climates like Florida, they might recommend an R-value of R30 to R49 for an uninsulated attic, while in colder northern climates, the recommendation could be as high as R49 to R60.

Blown-in insulation makes it straightforward to achieve a specific R-value. The depth of the material is directly related to its R-value. Installers use charts provided by the manufacturer that specify how many inches of their product are needed to reach a certain R-value. For example, to achieve R-38 with a particular fiberglass product that has an R-value of 2.5 per inch, the installer would need to blow it to a uniform depth of just over 15 inches.

Common Challenges and Smart Solutions

While blown-in insulation is a fantastic product, a successful outcome depends on proper installation and addressing a few potential issues.

- Settling: Over many years, some loose-fill materials can settle, which slightly reduces their depth and overall R-value. Cellulose is more prone to settling than fiberglass. However, professional installers account for this. When installing cellulose, they may intentionally install it at a slightly greater initial depth than required, so that even after it settles, it still delivers the target R-value. Dense-packing in walls completely prevents settling.

- Moisture: No insulation works well when it’s wet. Before installing insulation, it’s absolutely necessary to fix any roof leaks, plumbing drips, or ventilation issues that could introduce moisture into the space. A thorough inspection is the first step of any quality insulation job.

- Ventilation: In an attic, it’s important not to block the soffit vents, which are critical for proper airflow. These vents allow the attic to breathe, preventing moisture buildup in the winter and heat buildup in the summer. Installers use baffles or vents to ensure these airways stay open after the insulation is blown in.

Expert Tip: If you’re adding new blown-in insulation on top of old, existing insulation (a process called “capping”), make sure the old insulation is in good condition. If it’s wet, compacted, or contaminated with mold or pest droppings, it should be removed before the new layer is added.

Cost vs. Value: Analyzing the Investment

The cost of a blown-in insulation project depends on several factors: the type of material used, the size of the area being insulated, the required R-value (which determines the depth), and the complexity of the job. Generally, fiberglass is the least expensive material, followed by cellulose, with mineral wool being the premium option.

However, it’s best to think of insulation not as a cost, but as an investment in your home. The money you spend upfront is returned to you over time through lower energy bills. In fact, analysis by the North American Insulation Manufacturers Association (NAIMA) suggests that insulation is one of the few home improvement projects that can provide a return on investment of over 100%. Besides the monthly savings, it also improves your home’s resale value. A comfortable, energy-efficient home is a major selling point for potential buyers.

Putting Your Blown-In Insulation Strategy into Action

You now have a complete picture of blown-in insulation, from the different materials you can choose to the long-term value it provides. It’s clear that this is more than just a home improvement project; it’s a strategic upgrade that enhances comfort, saves money, and contributes to a healthier living environment. By creating a seamless thermal barrier, blown-in insulation tackles energy loss at its source, making it one of the most effective ways to improve a home’s performance.

Whether you’re looking to finally make your attic work for you instead of against you, or you want to fortify your walls against the elements, you’re now equipped with the knowledge to make an informed decision. Use this guide as a reference as you evaluate your home’s needs and explore your options.

Need Expert Guidance?

If you’re ready to see what a difference professional insulation can make, the team at Prestige Insulation Solutions LLC is here to help. We can provide a thorough assessment of your home and recommend the best solution for your specific situation and budget. For a no-obligation consultation, contact Prestige Insulation Solutions LLC today. You can reach us by phone at (850) 429-4969 or send an email to [email protected].

Sources

- U.S. Department of Energy – Provides information on air sealing techniques and their impact on home energy efficiency.

- ENERGY STAR – Offers data and recommendations on home insulation, including average savings from attic air sealing and insulation projects.

- North American Insulation Manufacturers Association (NAIMA) – Publishes information on the return on investment for insulation upgrades.

Frequently Asked Questions About Blown-In Insulation

How long does blown-in insulation last?

When installed correctly in a properly maintained space (i.e., no leaks or physical damage), blown-in insulation can last for the life of the house. It does not degrade or lose its insulating properties on its own, though it may settle slightly over the first few years.

Is the installation process messy?

Professionals take great care to minimize mess. They use tarps and plastic sheeting to protect your home. The material is contained within the hose as it’s run to the application area. For dense-packing walls, a high-quality vacuum is often used at the fill hole to capture any dust. Overall, it’s a much cleaner process than many people expect.

Is blown-in insulation safe for my family and pets?

Yes. Modern blown-in insulation materials are safe. Fiberglass is made from inert glass fibers. Cellulose is treated with non-toxic borates, which are a natural fire retardant. They do not release harmful chemicals or off-gas once installed. During installation, some dust is created, which is why technicians wear protective gear, but the area is cleaned thoroughly before they leave.

Can I put blown-in insulation over my old attic insulation?

In most cases, yes. As long as the existing insulation is dry and free of mold or contaminants, blowing a fresh layer on top is a great way to add R-value. This is a common and effective practice.

Can I rent a machine and do it myself?

While DIY is possible, it’s often not recommended for blown-in insulation. Professional installers have powerful, commercial-grade equipment that ensures the material is properly fluffed and installed at the correct density. Achieving an even layer at the right depth is harder than it looks. Improper installation can lead to subpar performance, and it’s easy to block vents or miss spots, compromising the result. [Link to: DIY vs. Professional Insulation Installation]

Does blown-in insulation attract pests?

No. Fiberglass and mineral wool are inorganic and have no nutritional value for pests. Cellulose is treated with borates, which act as an effective and safe insecticide and rodent repellent. Pests have no interest in nesting in or eating these materials.