Closed-cell spray foam insulation offers the most reliable performance in high humidity environments. Its impermeability to moisture, low absorption rate, and high R-value per inch make it highly effective for preventing mold, condensation, and structural issues. This type of insulation creates an air and moisture barrier that works well in humid climates, particularly in Gulf Coast regions like Florida, where humidity remains elevated year-round.

Open-cell spray foam and fiberglass may suit specific applications, but they carry limitations under consistently damp conditions. Blown-in cellulose can hold moisture, making it vulnerable to decay and microbial growth. Choosing the right insulation depends on the material’s moisture resistance, R-value stability, air-sealing capability, and suitability for the building structure.

This article draws from hands-on experience in Gulf-area insulation installation. It breaks down key material differences, includes data-backed insights, and addresses practical concerns relevant to coastal and subtropical zones.

Key Performance Comparison by Material Type

| Insulation Type | Moisture Resistance | R-Value per Inch | Air Seal Quality | Mold Resistance | Best Use Case |

|---|---|---|---|---|---|

| Closed-Cell Spray Foam | High | 6.5 – 7 | Excellent | Excellent | Roof decks, crawlspaces, humid interiors |

| Open-Cell Spray Foam | Moderate | 3.5 – 3.8 | Good | Moderate | Interior walls, conditioned attics |

| Fiberglass Batt | Low | 2.9 – 3.8 | Poor | Low | Dry climates, retrofit walls |

| Blown-In Cellulose | Low to Moderate | 3.2 – 3.8 | Moderate | Low to Moderate | Enclosed walls, attic retrofits |

| Rigid Foam Board (Polyiso) | High | 5.6 – 6.5 | Good | Good | Exterior sheathing, continuous insulation |

Why Closed-Cell Spray Foam Performs Best

Closed-cell spray foam acts as both an air and moisture barrier. This dual function is critical in high-humidity regions where moisture intrusion and condensation are constant threats. Its dense structure blocks water vapor transmission, reducing the risk of mold growth.

Bonus Tip

When insulating basement or crawlspace walls in the Gulf region, avoid exposed fiberglass or cellulose. Closed-cell foam is less prone to water retention and microbial decay.

Technical Performance Breakdown

| Specification | Closed-Cell Spray Foam | Open-Cell Spray Foam | Fiberglass | Cellulose |

|---|---|---|---|---|

| Vapor Permeability (perm) | <1 | 10 – 15 | High | Moderate |

| Compressive Strength (psi) | 25 – 40 | <5 | N/A | N/A |

| R-Value Retention Over Time | High | Moderate | Low | Low |

| Water Absorption | <1% | 5%+ | 30-50% | 15-20% |

| Air Leakage Rate | <0.02 cfm/sq ft | 0.1 – 0.2 | >1 | >0.5 |

Regional Considerations for Humid Areas

In Pensacola and other Gulf Coast regions, insulation must withstand elevated ambient moisture and frequent weather shifts. Materials that retain water or degrade under wet conditions can lead to poor indoor air quality, structural decay, and energy inefficiency.

According to data from the Building Science Corporation and DOE’s Building America Program, buildings in hot-humid zones perform best with materials that have low vapor permeability and high thermal resistance.

Bonus Tip

Ensure proper ventilation in tandem with insulation upgrades. Mechanical ventilation systems like ERVs help manage internal moisture buildup, particularly when using airtight insulation materials.

Things to Evaluate Before Choosing Insulation

- Building Type: Commercial or residential structures have different load-bearing and moisture tolerance requirements.

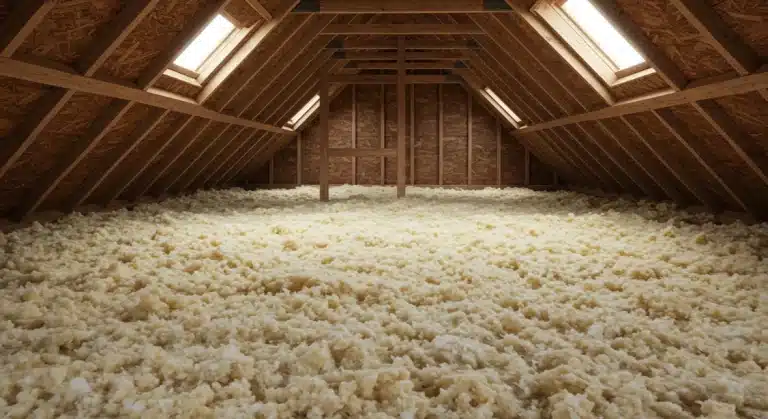

- Location of Application: Attics, crawlspaces, exterior walls, and basements require different moisture control strategies.

- Existing Material Conditions: Older insulation types like fiberglass may need full removal before upgrading.

- Air Sealing Goals: High-performance options like spray foam provide both insulation and air sealing, reducing the need for separate barriers.

Services Offered by Prestige Insulation Solutions

- Spray Foam Insulation: High-performance material that resists moisture and improves energy efficiency in humid climates.

- Insulation Removal: Safe removal of deteriorated or water-damaged insulation to prevent mold and improve performance.

- Roof Insulation: Thermal protection for roofing systems using spray foam to prevent heat gain and moisture intrusion.

- Residential Spray Foam Insulation: Moisture-resistant insulation for walls, attics, and crawlspaces in coastal homes.

Common Questions People Ask Before Choosing Insulation

What insulation holds up best in coastal climates?

Closed-cell spray foam resists humidity, wind-driven rain, and temperature shifts better than any other type.

Is fiberglass safe to use in humid regions?

Not in unconditioned spaces. Fiberglass can absorb moisture, leading to mold and loss of insulating performance.

Can spray foam trap moisture inside walls?

When installed correctly, closed-cell foam prevents vapor movement. Improper installation or lack of ventilation can cause internal buildup.

What insulation works for both air sealing and moisture control?

Closed-cell spray foam provides both functions effectively, eliminating the need for separate air or vapor barriers.

Conclusion

In high humidity environments, closed-cell spray foam outperforms other insulation types by providing an integrated air and moisture barrier with long-term stability. Material choice should align with moisture risk, structural design, and energy goals. Evaluate space-specific needs and avoid absorptive materials in unconditioned zones.

Contact Prestige Insulation Solutions

To assess insulation solutions suitable for high humidity and coastal climates, contact Prestige Insulation Solutions by phone at (850) 429-4969 or email at [email protected]. A site-specific assessment can clarify the most effective material and application method for your structure.

Frequently Asked Questions

How often does insulation need replacement in humid areas?

Closed-cell spray foam can last 30+ years if installed correctly. Fiberglass or cellulose may need replacement every 10–15 years in high humidity.

What risks come from ignoring moisture control in insulation?

Persistent moisture leads to mold, wood rot, pest activity, and energy loss. Poor insulation accelerates structural deterioration.

Can existing insulation be upgraded without full removal?

Depends on the material. Fiberglass can often be removed in sections, but wet or moldy areas must be replaced completely.

Are there code requirements for insulation in humid zones?

Yes. Building codes often require specific vapor retarders and minimum R-values. Consult local ordinances or certified contractors.

How does attic ventilation affect insulation in high humidity?

Poor ventilation traps heat and moisture, reducing insulation performance. Soffit and ridge vents or mechanical systems are often required.