For most residential properties, spray foam offers better insulation performance than fiberglass, especially in humid or variable climates like Florida’s. It creates an air-tight seal, has a higher R-value per inch, and contributes to moisture control. Fiberglass, though more affordable and easier to install, does not prevent air leakage and loses effectiveness when wet or compressed.

Choosing between spray foam and fiberglass comes down to long-term goals. Spray foam supports energy efficiency, structural integrity, and humidity management, while Fiberglass Insulation fits short-term budgets and simpler installations. This guide breaks down every aspect for a clear, informed decision.

Performance Breakdown by Material Type

| Feature | Spray Foam Insulation | Fiberglass Insulation |

|---|---|---|

| R-Value per inch | ~6.0 (Closed-cell), ~3.5 (Open-cell) | ~2.2 – 2.7 |

| Air Seal Capability | Excellent (closed-cell is air-impermeable) | Poor (allows airflow) |

| Moisture Resistance | High (closed-cell acts as vapor barrier) | Low (absorbs moisture, prone to mold) |

| Installation Area Coverage | Expands to fill gaps, total coverage | Requires cutting, may leave gaps |

| Lifespan | 30+ years | 10-25 years |

| Fire Resistance | Needs coating for fire safety | Naturally non-combustible |

| Sound Dampening | High (especially open-cell foam) | Moderate |

| Pest Resistance | High (sealed gaps deter nesting) | Low |

| Material Settling Risk | None | Moderate over time |

| Environmental Sensitivity | Stable in extreme temperatures | Performance drops in humidity |

Technical Insulation Properties

| Specification | Spray Foam (Closed-cell) | Spray Foam (Open-cell) | Fiberglass Batts |

|---|---|---|---|

| R-Value per inch | 6.0 – 7.0 | 3.5 – 3.8 | 2.2 – 2.7 |

| Vapor Permeability | <1 perm | 10+ perm | 30+ perm |

| Expansion Rate | Up to 100x | Up to 120x | None |

| Application Temperature Tolerance | -20°F to 180°F | -20°F to 180°F | 40°F to 120°F |

| Permitted Locations | Walls, attics, crawlspaces | Attics, walls, ceilings | Walls, attics, joists |

Regional Considerations for Florida Homes

High humidity and intense heat make thermal resistance and air sealing critical. Spray foam prevents conditioned air loss and resists moisture penetration – both major concerns in Gulf Coast climates. In contrast, fiberglass can absorb moisture from humid air, reducing thermal efficiency and inviting mold growth.

Bonus Tip: In older homes with vented attics, spray foam on roof decking can convert attics into semi-conditioned spaces, lowering HVAC load.

Common Use Cases Based on Firsthand Field Application

| Scenario | Recommended Option | Reason |

|---|---|---|

| New construction in humid area | Spray Foam | Complete seal, long-term energy savings |

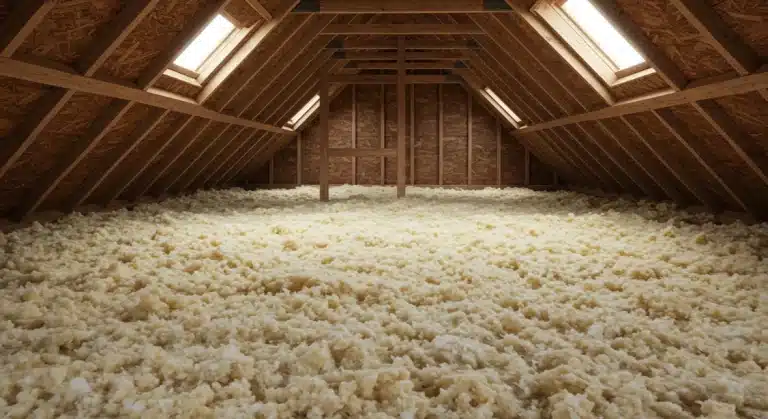

| Budget retrofit of attic | Fiberglass | Low cost and quicker installation |

| High noise reduction needed | Open-cell Spray Foam | Absorbs sound in interior walls or ceilings |

| Moisture-prone basement wall | Closed-cell Spray Foam | Water-resistant, adds wall strength |

Bonus Tip: For garages or sunrooms being converted into living spaces, closed-cell foam is more structurally supportive and prevents vapor intrusion.

What to Check Before Choosing an Insulation Type

- Building Age and Layout: Older homes with irregular framing benefit more from spray foam’s expansive fill.

- Moisture Exposure: Any area with past leaks, visible mold, or consistent dampness should avoid fiberglass.

- Energy Goals: Homes aiming for high-efficiency HVAC performance and consistent indoor temps should prioritize spray foam.

- Access and Project Timeline: Spray foam takes longer to cure and may require vacating the area temporarily.

- Fire Code Requirements: Some jurisdictions require intumescent coatings over foam; fiberglass does not.

Prestige Insulation Solutions Offers These Services for Your Home

- Spray Foam Insulation: Applied to seal gaps and improve thermal performance in all areas, including attics and walls.

- Fiberglass Insulation: Installed in rolls or batts for basic thermal resistance in standard framing cavities.

- Roof Insulation: Insulation applied directly to the underside of roof decks for energy efficiency.

- Insulation Removal: Safe removal of old or damaged insulation, including mold-prone fiberglass.

Immediate Questions People Ask Before Choosing

How long does spray foam take to install?

Spray foam usually takes 1-2 days depending on area size and weather. The curing phase can require temporary evacuation of treated spaces.

Can fiberglass insulation be reused?

No. Once removed or damaged, fiberglass loses integrity and should be replaced entirely.

Is spray foam safe for homes with kids or pets?

Yes, after proper curing and ventilation. Installers use personal protective equipment during application.

Does insulation help with soundproofing?

Yes. Spray foam, particularly open-cell, offers better sound dampening than fiberglass.

Final Thought on Choosing Spray Foam or Fiberglass

Spray foam outperforms fiberglass in most Florida homes when considering longevity, climate resistance, and sealing ability. Fiberglass fits short-term or lower-intensity needs but lacks the long-term stability. Select the material that supports your goals for comfort, structure, and energy performance.

Contact for More Expert Help on Insulation Choices

To discuss your home’s insulation needs or request an assessment, contact Prestige Insulation Solutions. Email [email protected] or call (850) 429-4969. Get direct insights from professionals with hands-on experience in Florida conditions.

Answers to Common Long-Term Questions

What maintenance does spray foam require?

None. Once installed and protected from UV exposure, it remains stable for decades.

Can insulation help reduce HVAC load?

Yes. Spray foam significantly reduces air leaks, lowering HVAC cycling and improving efficiency.

Will fiberglass lose effectiveness over time?

Yes. Settling, moisture, and compression all reduce fiberglass performance over the years.

Is it possible to install spray foam over old fiberglass?

Not recommended. Existing fiberglass must be removed for spray foam to bond and seal properly.

Which insulation works better in coastal areas?

Closed-cell spray foam performs best near coastal zones due to moisture control and structural enhancement.