Spray foam insulation provides superior moisture resistance and airtight sealing, making it an optimal choice for Navarre’s high-humidity environment. The Gulf Coast’s elevated dew points, frequent rain, and warm temperatures create conditions where conventional insulation types struggle to maintain consistent performance. Spray foam, with its closed-cell structure, prevents air and moisture infiltration that would otherwise reduce thermal performance and cause mold.

Prestige Insulation Solutions has observed that spray foam consistently outperforms alternatives in homes and businesses across coastal Florida. This content outlines key technical advantages, real-world application outcomes, and critical pre-installation insights based on field experience.

Regional Climate Challenges and How Spray Foam Responds

Moisture Intrusion and Condensation Control

Navarre’s average annual humidity exceeds 72%, with daily peaks often above 90%. These levels promote condensation in wall cavities and attics, which can degrade insulation and support mold growth. Closed-cell spray foam minimizes vapor transfer, reducing condensation risks on interior surfaces.

Air Sealing and Energy Efficiency

Gaps in conventional insulation allow humid air to enter wall assemblies, raising indoor humidity and cooling loads. Spray foam adheres directly to surfaces and expands to seal even hairline cracks, creating a thermal envelope that lowers HVAC strain and prevents moisture-driven air exchange.

Comparative Performance in Humid Environments

| Property | Spray Foam Insulation | Fiberglass Insulation | Blown-In Cellulose |

|---|---|---|---|

| Moisture Resistance | Excellent | Poor | Fair |

| Air Sealing Capability | High | Low | Low |

| Mold Resistance | High | Low | Moderate |

| Longevity in Humid Conditions | 20+ years | <10 years | 10-15 years |

| Thermal Efficiency (R-Value per inch) | 6.0-7.0 | 2.9-3.8 | 3.2-3.8 |

| Settling/Degradation Over Time | Minimal | Significant | Moderate |

Source: U.S. Department of Energy, Building America Climate-Specific Guidance (2023)

Technical Attributes That Matter

| Specification | Closed-Cell Spray Foam |

|---|---|

| R-Value (per inch) | 6.5 |

| Water Permeability | <1.0 perm |

| Expansion Ratio | 30x original volume |

| Air Infiltration Rate Reduction | >95% |

| Application Thickness (walls) | 2″ standard |

| Class A Fire Rating | Yes |

Source: ASTM C1029, ICC Evaluation Service Reports

Bonus Tip

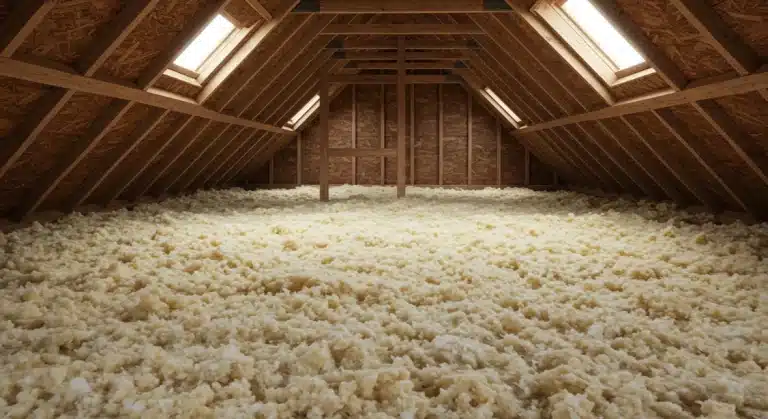

In high-humidity areas like Navarre, using spray foam in roof decks prevents warm, moist air from condensing inside attic cavities, especially when HVAC ducts run through those spaces.

Material Stability and Mold Resistance

Cellular rigidity of closed-cell spray foam prevents shrinkage, sagging, or settling over time. It doesn’t absorb water, which makes it unsuitable for mold growth even during prolonged periods of high humidity. This contrasts sharply with fiberglass, which loses R-value when wet and can harbor mold colonies.

Things to Consider Before Choosing Insulation

Building Envelope Assessment

Examine how moisture moves through your building. Structures with high exposure to wind-driven rain or built without vapor barriers will benefit more from spray foam.

Existing Materials

If old insulation is saturated, mold-prone, or degraded, removal is recommended before installation. Spray foam bonds best to clean substrates free from loose particles or water damage.

Application Area

Areas with persistent temperature swings and humidity, such as crawl spaces and roof decks, gain the most from the air sealing and moisture protection spray foam provides.

Bonus Tip

In older buildings with minimal cavity depth, spray foam offers high R-value performance without requiring extra structural modifications.

Closely Aligned Services Available

Prestige Insulation Solutions offers insulation types that perform reliably in humid coastal environments:

- Spray Foam Insulation: Forms a moisture-resistant barrier ideal for exterior walls, crawlspaces, and roofs.

- Spray Foam Roofing Insulation: Adds thermal and waterproofing value to flat and low-slope roof assemblies.

- Insulation Removal: Eliminates old or mold-affected materials before installing modern, efficient alternatives.

- Residential Spray Foam Insulation: Customized solutions for single-family and multi-unit homes along the coast.

Common Questions People Ask Before Installing Spray Foam

Does spray foam make a difference in energy costs?

Yes. Reduced air infiltration leads to decreased HVAC runtime. This often translates into lower monthly energy bills.

Can spray foam be applied over existing insulation?

It depends. Most cases require removal of existing insulation to ensure full adhesion and proper curing.

Is spray foam safe in humid climates?

Yes. Closed-cell foam is non-hygroscopic and doesn’t support microbial growth, making it ideal for humid regions like Navarre.

How long does installation take?

A typical home application can be completed in 1-2 days, depending on square footage and preparation needs.

Summary

Spray foam insulation meets Navarre’s humid climate challenges with superior sealing, moisture resistance, and long-term durability. It delivers consistent performance where other materials break down. Building owners should assess existing conditions and intended outcomes to determine suitability.

Get Expert Help When You Need It

For insulation that meets the specific demands of Navarre’s coastal climate, contact Prestige Insulation Solutions. Reach out by phone at (850) 429-4969 or email at [email protected] to schedule a consultation based on your property needs.

Frequently Asked Questions

How often should insulation be checked?

Conduct annual attic and crawlspace inspections, especially after storms, to ensure seals remain intact.

What maintenance is required?

Spray foam requires minimal upkeep. Check for physical damage after renovations or pest activity.

Can spray foam be used with other insulation types?

Hybrid systems are possible but must be planned correctly to prevent trapped moisture.

Is it compatible with vapor barriers?

Closed-cell foam functions as a vapor barrier, eliminating the need for additional layers in most applications.

What signs indicate a problem?

High humidity indoors, mold odor, or rising energy bills may suggest insulation failure or air leakage.