Spray foam insulation expands through a chemical reaction between two components: polyol resin and isocyanate. When installers mix these on-site, the reaction creates polyurethane foam that grows up to 100 times its liquid volume in seconds. This expansion seals gaps, cracks, and irregular spaces in walls, attics, and floors, forming an airtight barrier. In Bellview, FL, this process proves essential due to the area’s humid climate and varying temperatures.

This article breaks down the expansion science, local applications, and key factors to weigh. Readers gain a solid grasp of why Spray foam insulation outperforms traditional options in tight spaces. Prestige Insulation Solutions draws from years of hands-on work in the region to share reliable details on these methods.

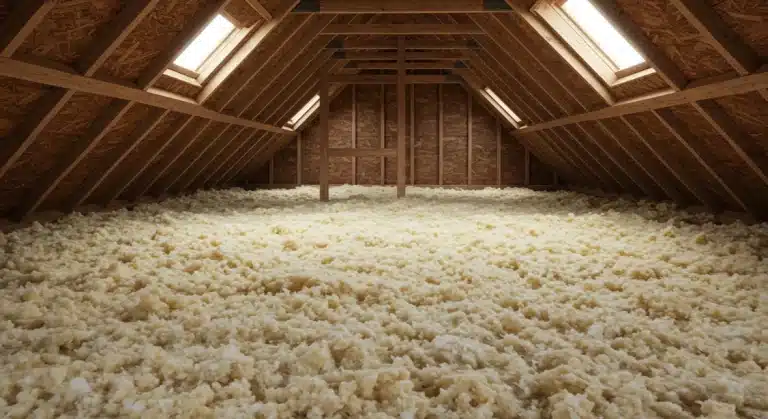

Basic Chemistry Behind the Expansion

The process starts with two liquid chemicals stored separately to prevent premature reaction. Technicians use a spray gun to combine them at the point of application. Heat from the reaction drives the expansion as carbon dioxide gas forms within the mixture.

Polyol resin acts as the base, while isocyanate provides the hardening agent. As they merge, the exothermic reaction releases heat and generates gas bubbles. These bubbles create the foam’s cellular structure, which can be open-cell for flexibility or closed-cell for density.

In practice, this means the foam adheres to surfaces like wood, metal, and concrete without needing extra fasteners. It fills voids that fiberglass batts or blown-in cellulose often miss.

Step-by-Step Expansion Mechanism

First, the liquids hit the surface and begin reacting immediately. Within 4 to 8 seconds, the mixture turns creamy and starts to rise. Full expansion occurs in about 20 to 60 seconds, depending on temperature and humidity.

The foam cures fully in hours, hardening into a solid mass. Closed-cell versions expand more aggressively, up to 30 times the volume, making them ideal for structural support. Open-cell foam expands more gradually but offers better sound absorption.

Factors like ambient temperature influence the rate. In Bellview’s warm, humid summers, installers adjust ratios to control rise and avoid over-expansion that could warp surfaces.

Bonus Tip from Field Experience

Test small areas first in high-humidity spots. This prevents issues like uneven curing seen in past jobs during Florida’s rainy seasons.

Why This Matters in Bellview’s Climate

Bellview experiences hot, humid summers with average highs near 92°F and mild winters around 60°F. Frequent rain and hurricane risks demand insulation that blocks moisture and maintains energy efficiency.

Spray foam’s expansion creates a seamless seal, reducing air leaks by up to 24 times compared to traditional methods, as noted in a study by Oak Ridge National Laboratory. This seal prevents humid air from infiltrating, cutting mold risks in the region’s sticky environment.

Local building codes in Escambia County emphasize vapor barriers. Spray foam meets these by forming its own moisture-resistant layer, especially closed-cell types with high R-value per inch.

Market data shows Florida homes with spray foam save 10-20% on cooling costs annually. The U.S. Energy Information Administration reports that air sealing like this addresses 40% of energy loss in southern climates.

Comparison of Insulation Types

Different materials handle gaps differently. Here’s a table outlining key differences:

| Insulation Type | Expansion Capability | R-Value per Inch | Moisture Resistance | Best for Bellview Gaps |

|---|---|---|---|---|

| Spray Foam (Closed-Cell) | Dense (30x volume) | 6.5 | Excellent | Tight, irregular spaces in humid areas |

| Spray Foam (Open-Cell) | Expansive (100x volume) | 3.5 | Good | Soundproofing in attics |

| Fiberglass Batts | None | 3.1 | Poor without barriers | Standard wall cavities, but leaves gaps |

| Blown-In Cellulose | Low settling | 3.2 | Moderate | Loose fills, but compresses over time |

This table highlights why spray foam excels in filling every nook without compression issues common in Bellview’s variable weather.

Things to Consider Before Making a Decision

Assess home age and structure first. Older Bellview homes built in the 1970s may have settling foundations that affect gap sizes. Measure total square footage to estimate material needs accurately.

Check for existing insulation. Adding spray foam over old layers risks over-insulation and heat buildup in attics during summer peaks.

Budget plays a role. Initial costs run higher, but long-term savings on utility bills offset this in Florida’s energy market. Consult local codes for permit requirements, as Escambia County mandates professional installation for spray foam.

Health aspects matter too. Ensure low-VOC products to avoid off-gassing in enclosed spaces.

Bonus Tip from Field Experience

Inspect for pest entry points before application. Rodents in coastal Florida can chew through barriers, so seal those first.

Common Questions

Homeowners often wonder about installation time?

A typical 1,500 sq ft home takes one to two days, depending on access.

Another concern involves environmental impact?

Modern formulations use HFO blowing agents with lower global warming potential than older HFCs.

Durability questions arise frequently?

Properly installed foam lasts 80 years or more, resisting settling or degradation in humid conditions.

Bonus Tip from Field Experience?

Ventilate workspaces during application. Even low-VOC foams benefit from fresh air flow to speed curing in Bellview’s still, humid air.

Key Takeaways

Spray foam expands via a rapid chemical reaction, filling gaps that other insulations can’t reach. In Bellview, this seals against humidity and heat loss effectively. Weigh home specifics, climate needs, and codes before proceeding. Evaluate your setup, energy goals, and budget to decide if it fits.

Ready to Learn More

For detailed advice on insulation options suited to Bellview homes, reach out to Prestige Insulation Solutions at (850) 429-4969 or [email protected]. Discussions focus on your property’s unique needs and local conditions, helping clarify next steps without commitment. This step ensures informed choices for lasting comfort. (72 words)

Sources

- Oak Ridge National Laboratory – Research on building envelope performance, including air leakage reduction from spray foam applications

- U.S. Energy Information Administration – Data on residential energy consumption and savings from insulation in southern U.S. states

- Building Science Corporation – Articles and studies on insulation effectiveness in humid climates, supporting energy efficiency claims

Frequently Asked Questions

How Does Temperature Affect Spray Foam Expansion in Florida?

Higher temperatures speed up the reaction, leading to faster expansion. In Bellview’s 90°F summers, crews lower the chemical temperature to 120°F for control. This prevents bridging over gaps instead of filling them.

Can Spray Foam Shrink Over Time?

Quality products show minimal shrinkage, under 1%. Closed-cell types hold shape best against Florida’s thermal swings, maintaining the seal for decades.

Is Spray Foam Safe for DIY in Small Areas?

Professional tools ensure even mixing, but kits exist for minor jobs. Still, hire experts for structural areas to avoid voids that compromise efficiency.

Does Expansion Damage Surfaces?

When applied correctly, it adheres without harm. Over-application in confined spaces can exert pressure, so pros calculate depth limits based on cavity size.

How Does It Compare to Other Insulations for Energy Savings?

It outperforms by sealing air paths, potentially saving 15% more on bills than batts alone. Data from Building Science Corporation confirms this in humid zones like northwest Florida.