Introduction

Choosing the right insulation is a key decision for homeowners looking to improve energy efficiency, indoor comfort, and cost savings. Blown-in insulation and fiberglass batts are two of the most widely used options. Each has its own advantages, and understanding the differences can help determine the best choice for your home in 2025.

This guide breaks down the performance, cost, installation process, and durability of both materials, ensuring you have the details needed to make an informed decision.

Comparing Blown-In Insulation and Fiberglass

Material Composition and Structure

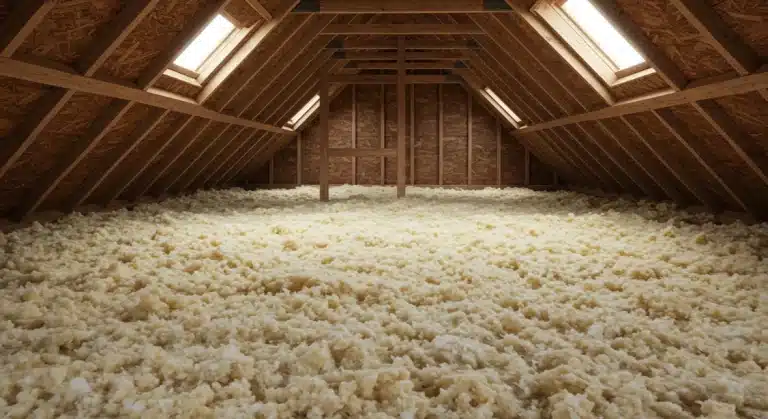

- Blown-In Insulation: Made from loose cellulose, fiberglass, or mineral wool fibers. This insulation is applied using a machine that blows the material into attics, walls, and other cavities.

- Fiberglass Batt Insulation: Comes in pre-cut rolls or panels made of fine glass fibers. These batts are manually placed between wall studs, floor joists, or attic rafters.

Energy Efficiency and R-Value

R-value measures insulation’s ability to resist heat transfer. A higher R-value means better insulation.

- Blown-in insulation typically has an R-value of R-3.1 to R-3.8 per inch for cellulose and R-2.2 to R-2.7 per inch for fiberglass.

- Fiberglass batts usually have an R-value of R-2.9 to R-3.8 per inch.

Blown-in insulation provides better coverage, reducing air gaps and enhancing thermal performance.

Installation Process

- Blown-In Insulation: Requires specialized equipment to distribute the material evenly. It is best applied by professionals but can be done as a DIY project with rental equipment.

- Fiberglass Batt Insulation: Comes in pre-cut sections and is manually fitted between framing members. This installation is more straightforward but can leave gaps if not installed properly.

Durability and Maintenance

- Blown-In Insulation: Cellulose-based insulation can settle over time, requiring periodic top-ups. Fiberglass varieties have minimal settling.

- Fiberglass Batts: Retains its shape but can be compressed over time, reducing effectiveness. Proper installation is key to avoiding performance loss.

Moisture and Mold Resistance

Moisture resistance is a major factor in insulation performance.

- Blown-in cellulose absorbs moisture more easily than fiberglass, making it more susceptible to mold and rot if not properly installed with vapor barriers.

- Fiberglass batts are moisture-resistant but can still trap moisture if exposed to leaks, leading to potential mold growth.

Fire Safety

- Blown-in cellulose is treated with fire-retardant chemicals, making it relatively fire-resistant.

- Fiberglass batts are naturally non-combustible but can lose effectiveness when exposed to extreme heat.

Choosing the Right Insulation for Your Home

The best insulation choice depends on your home’s structure, climate, budget, and long-term energy savings.

- Best for Existing Homes & Retrofits: Blown-in insulation is ideal for upgrading attics or adding insulation to existing walls without major renovations.

- Best for New Construction: Fiberglass batts are often used in new builds where open walls allow for easier installation.

- Best for High Moisture Areas: Fiberglass performs better in humid regions where moisture resistance is a priority.

- Best for Maximum Energy Efficiency: Blown-in cellulose offers the best air sealing and overall performance.

Professional Assistance for Insulation Installation

Upgrading insulation can lead to lower energy costs and increased comfort. Prestige Insulation Solutions specializes in professional installation, ensuring your home benefits from the best insulation for your specific needs.

Conclusion

Both blown-in insulation and fiberglass batts offer distinct benefits. If energy efficiency, air sealing, and soundproofing are priorities, blown-in insulation is the stronger option. If affordability and ease of installation matter more, fiberglass batts may be the better choice. Evaluating factors like climate, budget, and home structure will help determine the best fit for your needs.

For expert guidance and installation services, reach out to Prestige Insulation Solutions at (850) 429-4969 or [email protected].

FAQs

1. Which insulation type has better soundproofing capabilities?

Blown-in cellulose provides superior soundproofing because it is denser and fills gaps more effectively than fiberglass batts.

2. Can I install insulation myself, or should I hire a professional?

Fiberglass batts can be installed as a DIY project, but blown-in insulation often requires professional equipment for even distribution.

3. How long does each insulation type last?

Both options can last 20-30 years, though blown-in cellulose may need topping off due to settling.

4. Which insulation is better for extreme cold or hot climates?

Blown-in insulation, particularly cellulose, provides better overall thermal performance in extreme temperatures.

5. Does insulation affect indoor air quality?

Properly installed insulation improves air quality by reducing drafts and minimizing dust circulation.

6. What’s the best insulation for attics?

Blown-in insulation is preferred for attics because it provides uniform coverage without leaving gaps.

7. How does insulation impact my energy bill?

High-quality insulation reduces heating and cooling costs by improving energy efficiency.

8. Is there any government incentive for upgrading insulation?

Some states and utility companies offer rebates or tax incentives for energy-efficient insulation upgrades.

9. Can blown-in insulation be removed?

Yes, it can be vacuumed out by professionals if necessary.

10. Is fiberglass insulation safe for homes?

Yes, modern fiberglass batts are non-toxic and safe when properly installed.