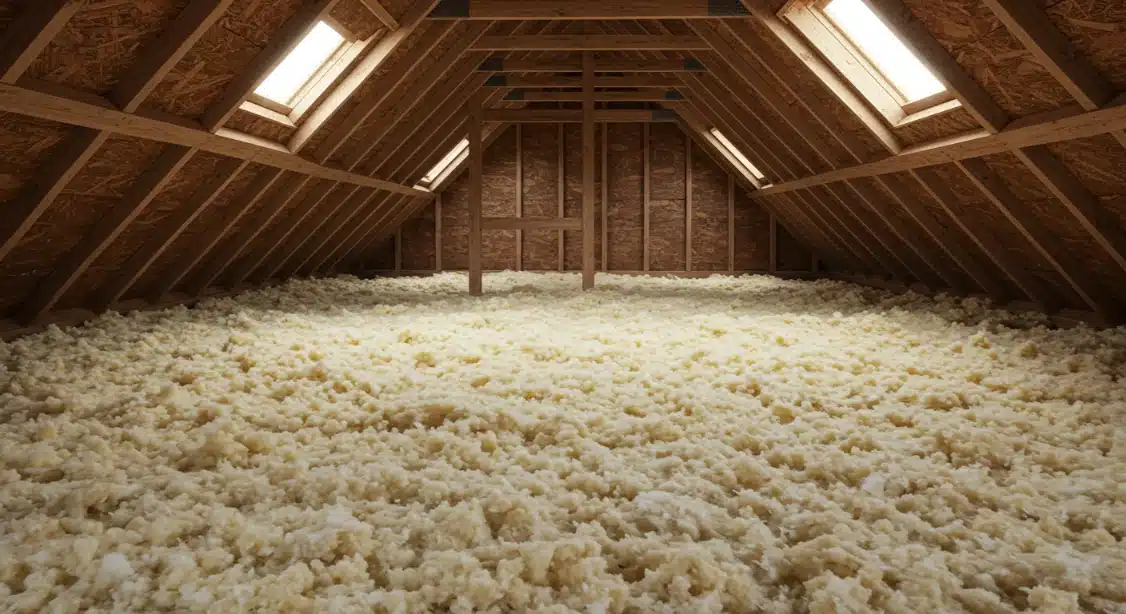

Blown-in insulation stops ice dams by creating a consistent temperature barrier between your living space and roof, preventing the warm air that melts snow from escaping into the attic. This thermal separation keeps the roof surface cold enough to prevent snow from melting and refreezing at the eaves, which is what creates dangerous ice dams. The effectiveness comes from the insulation’s ability to fill gaps and create a continuous thermal blanket that traditional insulation methods often miss. This article will explain the science behind ice dam formation, why blown-in insulation is particularly effective, and what you need to know before making an investment in your home’s protection.

Understanding Ice Dams and Their Causes

Ice dams form when heat from your living space warms the roof deck above the attic, causing snow to melt. The water runs down the roof until it reaches the colder eaves, where it refreezes into a ridge of ice. As this cycle continues, water can back up under the shingles and leak into your home, causing extensive damage to walls, ceilings, and insulation. The problem isn’t the snow or cold weather – it’s the temperature difference across your roof surface.

Most homeowners don’t realize that ice dams indicate a fundamental problem with their attic’s thermal performance. According to research from the Building Science Corporation, proper attic insulation should keep the roof surface within 5-10 degrees of outdoor air temperature, regardless of how warm it is inside your home. When the roof deck stays cold, snow melts naturally and evenly, preventing the freeze-thaw cycle that creates ice dams.

Ice dam damage can be incredibly substantial. Industry data reveals that ice dam-related insurance claims often involve significant financial impact per incident, and this doesn’t even include the potential for pervasive mold growth and long-term structural damage. Prioritizing prevention through proper insulation is a far more economically sound strategy than addressing the extensive aftermath.

How Blown-In Insulation Works Against Ice Dams

Blown-in insulation creates a superior thermal barrier by filling every void and gap in your attic space, including hard-to-reach areas around framing members, electrical boxes, and plumbing penetrations. Unlike batts or rolls that can leave gaps, the loose-fill material compacts around obstacles, creating a continuous insulation blanket with minimal thermal bridging. This comprehensive coverage prevents warm air from escaping into the attic and warming the roof deck from below Insulation Institute.

The key physics principle at work is conduction – the transfer of heat through materials. Blown-in insulation reduces conduction by trapping air in millions of tiny pockets within the insulation material. Different types of blown-in insulation achieve this through various means:

- Cellulose: Made from recycled paper treated with fire retardants, it achieves R-values of 3.2-3.8 per inch

- Fiberglass: Composed of tiny glass fibers, it provides R-values of 2.2-2.7 per inch

- Mineral wool: Created from rock or slag fibers, it offers R-values of 3.0-3.3 per inch and superior fire resistance

The higher the R-value per inch, the better the insulation resists heat flow. For ice dam prevention, most cold climates recommend R-49 to R-60 insulation in attics, which typically translates to 16-20 inches of blown-in material, depending on the type used.

Types of Blown-In Insulation for Ice Dam Prevention

Cellulose Insulation

Cellulose insulation consists of about 85% recycled paper fibers, primarily newsprint, treated with borate compounds for fire resistance and pest deterrence. It’s the most popular choice for attic insulation due to its higher R-value per inch and excellent air-sealing properties. The dense packing of cellulose (typically 3.0-3.5 pounds per cubic foot) helps it resist settling and maintain its thermal performance over time.

Fiberglass Insulation

Blown-in fiberglass uses tiny glass fibers that are spun into a wool-like material. It’s lighter than cellulose and non-combustible without added chemicals. While it has a lower R-value per inch than cellulose, it’s moisture-resistant and won’t support mold growth. Modern blown fiberglass uses a formaldehyde-free binder and contains up to 70% recycled content.

Mineral Wool Insulation

Mineral wool insulation comes in two forms: rock wool and slag wool. It offers the best fire resistance of any insulation type, withstanding temperatures over 2000°F. It also provides excellent sound dampening and is naturally water-repellent. The higher cost makes it less common for residential applications, but its performance characteristics make it ideal for certain situations.

| Insulation Type | R-Value per Inch | Key Advantages | Best For |

|---|---|---|---|

| Cellulose | 3.2-3.8 | Highest R-value, air-sealing, recycled content | Most homes, budget-conscious projects |

| Fiberglass | 2.2-2.7 | Moisture resistant, non-combustible, lightweight | Humid climates, fire safety priority |

| Mineral Wool | 3.0-3.3 | Superior fire resistance, sound dampening, water-repellent | High-risk fire areas, soundproofing needs |

Installation Process and Key Considerations

Proper installation of blown-in insulation requires specific equipment and techniques to achieve the stated R-value and performance. Professional installers use specialized blowing machines that agitate the insulation material and distribute it evenly through hoses. The process involves measuring the attic space, calculating the required depth based on the chosen insulation type, and ensuring uniform coverage without gaps or compression.

Air sealing should precede insulation installation for maximum effectiveness. This includes caulking around electrical boxes, sealing plumbing penetrations, weatherstripping attic hatches, and using foam sealant around framing members. Research from Energy Star shows that combining proper air sealing with insulation can reduce heating and cooling costs by up to 15% annually.

Ventilation works in conjunction with insulation to prevent ice dams. A well-ventilated attic allows cold air to enter through soffit vents and exit through ridge or gable vents, carrying away any heat that does escape from your living space. The recommended ventilation ratio is 1 square foot of ventilation for every 300 square feet of attic floor space, evenly split between intake and exhaust vents.

Bonus Tip: In cold climates like Minnesota or Wisconsin, local building codes may require higher insulation levels than the federal minimums. Always check local requirements before starting your insulation project.

Bonus Tip: For cathedral ceilings or low-slope roofs where traditional blown-in insulation isn’t feasible, consider dense-pack cellulose installed in framing cavities combined with rigid foam insulation above the roof deck for maximum ice dam protection.

Things to Consider Before Making a Decision

Before investing in blown-in insulation for ice dam prevention, evaluate several key factors that affect both performance and cost. Your climate zone plays a significant role in determining the required R-value and whether additional measures like ice-and-water shield membranes are necessary. Homes in northern Minnesota will need more insulation than those in milder regions of the same state.

The condition of your existing insulation matters too. If you already have some insulation, it might need to be removed or redistributed before adding new material. Compressing old insulation reduces its effectiveness and can create moisture problems if not addressed properly. A professional energy audit can identify air leaks, insulation gaps, and ventilation issues that should be corrected during the insulation project.

Consider accessibility challenges. Attics with limited headroom, complex framing, or numerous obstructions may require more labor time and specialized equipment. Some homes may have knob-and-tube wiring in the attic that must be replaced or protected before insulation can be safely installed, as covering these old electrical systems with insulation creates fire hazards.

Market data indicates that homeowners recoup an average of 107% of insulation improvement costs at resale, making it one of the few home improvements that pays for itself. However, the primary benefit remains the prevention of costly ice dam damage and improved comfort throughout the winter months.

Bonus Tip: If you’re planning to finish your attic space, consider installing insulation on the roof rafters rather than the attic floor. This approach preserves ventilation while keeping the roof deck cold, but requires careful moisture management to prevent condensation issues.

Take Action Against Ice Dams

Blown-in insulation provides one of the most effective solutions for preventing ice dams by maintaining consistent roof temperatures and stopping heat transfer from your living space to the attic. The combination of proper insulation depth, complete air sealing, and adequate ventilation creates a system that protects your home from water damage while improving year-round comfort and energy efficiency.

Before making decisions about insulation, assess your current situation, including existing insulation levels, ventilation adequacy, and any moisture issues. Consider consulting with insulation professionals who can perform energy audits and recommend solutions specific to your home’s needs and local climate requirements. The investment in quality insulation typically pays for itself through energy savings and prevented damage costs.

Get Professional Assessment

For homeowners experiencing ice dams or concerned about inadequate attic insulation, Prestige Insulation Solutions offers comprehensive evaluations and installation services. Their team can assess your current insulation levels, identify air leakage points, and recommend the right type and depth of blown-in insulation for your specific situation. Contact Prestige Insulation Solutions at [email protected] or call (850) 429-4969 to schedule a consultation and protect your home from ice dam damage this winter.

Frequently Asked Questions

Does blown-in insulation eliminate all ice dams?

No insulation system can completely eliminate ice dams in every situation. Extreme weather conditions, inadequate ventilation, or roof design flaws can still contribute to ice dam formation despite proper insulation. However, blown-in insulation dramatically reduces the likelihood and severity of ice dams by addressing the primary cause – heat loss from the living space.

How much insulation do I need for ice dam prevention?

The required insulation depth varies by climate and insulation type. For most northern climates, R-49 to R-60 is recommended, which translates to approximately 14-18 inches of cellulose or 17-22 inches of fiberglass. Local building codes provide specific minimum requirements based on your location’s heating degree days.

Will adding insulation make my existing ventilation problems worse?

Properly installed insulation shouldn’t worsen ventilation issues, but it can reveal existing problems. When insulation stops heat loss through the attic floor, the roof temperature becomes more dependent on proper ventilation. If your vents are blocked or inadequate, you may experience new condensation problems after adding insulation.

Is blown-in insulation safe for older homes?

Blown-in insulation is generally safe for older homes when installed correctly. However, professionals should inspect for asbestos in existing insulation, knob-and-tube wiring, and moisture problems before installation. Modern cellulose contains fire retardants that make it safer than many insulation types used in older constructions.

Can blown-in insulation help with summer cooling costs?

Yes, the same thermal barrier that prevents heat loss in winter also reduces heat gain in summer. Proper attic insulation can lower cooling costs by 10-20% in hot climates by preventing heat transfer through the ceiling from the hot attic space.

Sources

- Building Science Corporation – Research organization providing scientific information on building performance and insulation requirements

- Energy Star – EPA program offering energy efficiency information and requirements for proper insulation and air sealing

- Insulation Institute – Industry resource providing technical data on insulation types, R-values, and installation standards