Blown-in insulation provides a rapid return on investment, mostly because it costs significantly less to install than other retrofit options while delivering immediate reductions in monthly energy bills. Homeowners often see the project pay for itself in just two to five years, making it one of the fastest-financing home improvements available. Prestige Insulation Solutions has evaluated countless homes and found that the combination of low material costs, quick installation times, and high thermal performance creates a financial equation that works in the homeowner’s favor very quickly. This guide explains exactly how that return occurs, which materials work best, and which factors influence the payback timeline.

The Mechanics of Immediate Savings

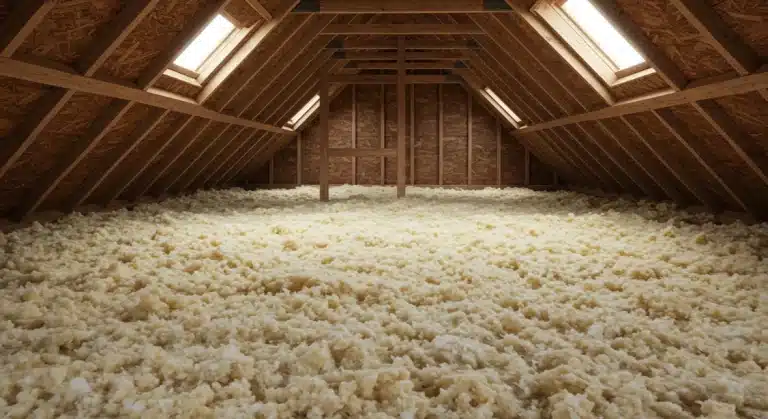

The financial speed of blown-in insulation comes down to physics and installation efficiency. Traditional fiberglass batts often leave gaps around studs, wires, and pipes, allowing conditioned air to escape. Blown-in materials, whether fiberglass or cellulose, fill every nook and cranny. This creates a continuous thermal blanket that stops air movement.

When heated or cooled air stays inside the living space, the HVAC system runs for shorter periods and less frequently. This reduction in run time is the primary driver of savings. A home that loses 30% of its conditioned air through the attic will see an immediate drop in energy usage once that air loss is stopped. According to Energy Star, sealing air leaks and adding insulation in attics can save homeowners up to 15% on heating and cooling costs. That percentage applies directly to the bottom line every single month, starting immediately after installation.

Material Costs and Efficiency

Not all insulation offers the same return on investment. The cost of the material and its R-value per inch determine how fast the project breaks even.

Cellulose Insulation Made from recycled paper, cellulose is denser than fiberglass. It is often treated with borates to resist fire and pests. Because it is heavier, it settles well and resists airflow better than many other materials. This density gives it a higher R-value per inch in practical applications, meaning homeowners get more thermal resistance for the same thickness.

Fiberglass Blown-In This material consists of glass fibers spun into wool. It is lighter and less expensive than cellulose but can be more prone to air movement if the depth isn’t sufficient. However, it resists moisture better than cellulose in extremely humid conditions.

The table below compares the two common materials in terms of cost and performance.

| Material Type | R-Value per Inch | Moisture Resistance | Settling Rate |

|---|---|---|---|

| Blown-in Cellulose | R-3.2 to R-3.8 | Moderate (absorbs water) | Low (compacts slightly) |

| Blown-in Fiberglass | R-2.2 to R-2.7 | High (resists water) | Very Low |

Data from the Insulation Institute suggests that while fiberglass has a lower upfront cost, cellulose often provides a faster return on investment in climates with extreme temperatures due to its superior air-blocking properties.

Why Installation Speed Matters

Time is money, even in home improvement projects. Blown-in insulation is exceptionally fast to install compared to batts or rigid foam. A crew can install blown-in material in a matter of hours, whereas cutting and fitting batts can take days.

This speed lowers the labor cost component of the quote. Since labor is a significant portion of any home retrofit, reducing the hours required to complete the job directly lowers the total investment. A lower total investment means the monthly energy savings recoup the costs much faster. In the insulation industry, this is often referred to as “low barrier to entry.”

Bonus Tip for Retrofit Projects

For existing homes, professionals often recommend installing ” dams” or baffles before blowing in material. These keep the insulation away from the soffit vents. Blocking these vents with insulation can cause moisture buildup and roof rot, which would destroy any financial gains from the project. Proper ventilation ensures the roof stays cool and dry, protecting the home’s structure.

Regional Climate Factors

Location plays a massive role in calculating the return on investment. In the service area covered by Prestige Insulation Solutions, the climate is hot and humid for much of the year. In these regions, the “stack effect” works in reverse. Hot air enters the attic through ventilation and radiates down into the living space.

Proper insulation blocks this radiant heat transfer. The U.S. Department of Energy recommends specific R-values for different zones. In hotter zones, a higher R-value in the attic is often recommended to resist the intense heat gain. The investment pays off quickly here because air conditioning is the home’s largest energy consumer. Reducing the cooling load by 20% results in substantial savings during the long summer months.

Things to Consider Before Making a Decision

Before signing a contract or renting a machine, homeowners must evaluate several specific factors to ensure the investment actually yields the expected returns.

- Air Sealing First: Insulation does not stop air flow; it slows heat transfer. Before adding new insulation, gaps around ceiling lights, plumbing stacks, and chimneys must be sealed with spray foam or caulk. If these leaks are not sealed, the blown-in insulation will actually hide them, making them harder to fix later. Dirty spots on existing insulation often indicate air leaks that need attention.

- Existing Insulation Levels: If the home already has 12 inches of insulation, adding another 6 inches might offer diminishing returns. The goal is to reach the recommended R-value for the zone, not necessarily to bury the attic in material. Check current depths before adding more.

- Roof Condition: If a roof has leaks or is near the end of its life, adding insulation underneath it is unwise. A roof replacement requires tearing out the insulation. It makes more financial sense to replace the roof first and then install fresh insulation.

- Ventilation: Ensure the attic has proper intake and exhaust vents. Insulation needs a dry environment to maintain its R-value. If an attic traps moisture, the insulation can lose effectiveness or even mold.

Final Thoughts on the Investment

Blown-in insulation offers a clear and rapid return on investment by attacking the largest energy expense in a home, heating and cooling. The math is straightforward. The initial cost is low, the installation is fast, and the monthly savings are immediate and recurring. Homeowners looking to improve comfort and reduce utility bills will find few other projects that offer the same speed of payback as attic insulation. Evaluating the current state of the attic, sealing air leaks, and choosing the right material for the specific climate will maximize those returns.

Get in Touch with Prestige Insulation Solutions

For homeowners ready to improve their home’s energy efficiency, a professional assessment is the best next step. Prestige Insulation Solutions can evaluate specific insulation needs and provide a clear estimate of potential savings. To discuss a project or schedule an inspection, contact the team at [email protected] or call (850) 429-4969.

Frequently Asked Questions

How long does blown-in insulation last?

High-quality materials can last for the life of the home, typically 40 to 100 years, as long as they remain dry and undisturbed. Cellulose is treated to resist fire and pests, and fiberglass does not degrade over time.

Will this lower my taxes?

There are often federal tax credits for energy-efficient home improvements. Checking the current IRS guidelines or the Database of State Incentives for Renewables & Efficiency (DSIRE) can reveal specific credits that further speed up the return on investment.

Does insulation help with soundproofing?

Yes, blowing insulation into walls or attics significantly reduces noise transmission. It acts as a sound dampener, making it a good choice for home offices, bedrooms, or media rooms.

What is the difference between batt and blown-in?

Batts are rolls of pre-cut insulation fitted between joists. Blown-in is loose material sprayed into place. Blown-in creates a custom fit that covers irregular shapes and obstructions much better than batts, leading to fewer gaps and better overall performance.

Is there a smell?

New insulation may have a slight odor for a few days, but it usually dissipates quickly. Cellulose, being made of newspaper, might have a dusty paper smell initially. Fiberglass is generally odorless.

Sources

- Energy Star – Energy Star is a U.S. government program that provides information on energy efficiency, including data on savings from sealing and insulating homes.

- Insulation Institute – The Insulation Institute is a resource created by the North American Insulation Manufacturers Association (NAIMA), providing industry data, research, and technical specifications on insulation materials.

- Oak Ridge National Laboratory – ORNL is a multiprogram science and technology laboratory managed by UT-Battelle, LLC for the U.S. Department of Energy, providing extensive research on building envelopes and thermal performance.