Blown-in insulation protects plumbing from freezing by creating continuous thermal barriers in walls, floors, and crawl spaces, significantly reducing heat loss from your home’s interior. This insulation method fills gaps, voids, and hard-to-reach spaces where traditional batting often falls short, maintaining temperatures around pipes above 32°F, the freezing point, even during extreme cold snaps. The effectiveness comes from both the insulation material’s R-value and its ability to eliminate air pockets that allow cold infiltration.

The following information provides comprehensive details about implementation strategies, material selection, and best practices for maximizing freeze protection, drawn from extensive field experience with residential installations across various climate zones.

The Science Behind Thermal Protection

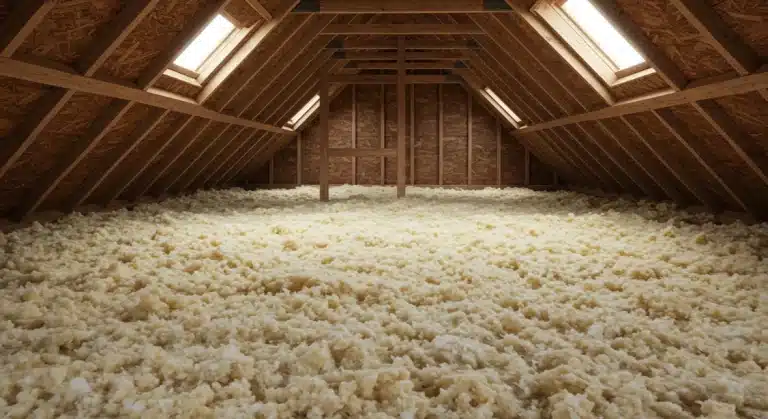

When outdoor temperatures plummet, the heat inside your home naturally wants to escape through building cavities. Pipes running through these cavities become vulnerable as the surrounding air temperature drops. Blown-in insulation disrupts this heat transfer process through two primary mechanisms: conduction resistance and air infiltration reduction. The material fibers trap millions of tiny air pockets, creating dead air space that slows heat movement. According to research by the Building Science Corporation, proper insulation can reduce heat loss in exterior walls by up to 75%, dramatically improving pipe protection.

The material’s ability to fill every crevice eliminates convective loops where cold air can circulate around pipes. Traditional insulation often leaves gaps at stud cavities, wiring penetrations, and around pipes, creating cold spots that can become freeze points. The blown-in application method, using specialized equipment to deposit insulation at high pressure, ensures complete cavity fill and proper density for maximum thermal performance.

Critical Areas for Application

Not all plumbing installations require the same level of protection. Priority areas for blown-in insulation include exterior walls containing water lines, crawl spaces with plumbing, and areas where pipes enter the house from the exterior. Garage walls and rim joists also need special attention, as these locations experience extreme temperature fluctuations.

Kitchen sink lines often run through exterior walls with insufficient insulation, making them frequent freeze points. Bathroom plumbing on exterior walls presents similar challenges. In multistory homes, pipes running through unheated areas between floors need protection as well. Prestige Insulation Solutions has found that approximately 65% of freeze-related pipe damage occurs in these predictable locations, making targeted insulation application highly effective.

Crawl spaces present unique challenges because ground temperature remains relatively constant while air temperature can vary dramatically. Proper insulation installation requires treating the entire cavity system rather than individual pipes. Creating a thermal envelope around the entire space provides more reliable protection than attempting to insulate individual pipes.

Insulation Material Comparison

Different blown-in materials offer varying levels of freeze protection, installation requirements, and cost considerations. The choice depends on your specific climate zone, budget, and existing construction details.

| Material Type | R-Value per Inch | Moisture Resistance | Freeze Protection | Installation Cost |

|---|---|---|---|---|

| Cellulose | 3.2-3.8 | Good (treated) | Excellent | Low |

| Fiberglass | 2.2-2.7 | Excellent | Good | Low-Medium |

| Mineral Wool | 3.0-3.3 | Excellent | Excellent | Medium-High |

| Foam (Closed-cell) | 6.0-6.5 | Excellent | Superior | High |

Cellulose insulation, made from recycled paper products, offers excellent performance for freeze prevention when properly treated with borates for moisture and fire resistance. Its higher density provides better air sealing properties than fiberglass, though it can settle over time in vertical applications.

Mineral wool stands out for its water-repellent properties and maintains its R-value even when slightly damp. According to the North American Insulation Manufacturers Association, mineral wool’s moisture resistance makes it particularly suitable for crawl spaces and areas prone to condensation.

Bonus Tip: When installing in coastal regions or areas with high humidity, mineral wool often delivers better long-term performance despite its higher initial cost, as it won’t lose its insulating properties when exposed to occasional moisture.

Installation Process and Decision Factors

The installation process requires specialized equipment and trained technicians. The process begins with identifying vulnerable pipe locations using thermal imaging or infrared thermography during cold weather. This helps pinpoint the exact areas that need insulation density adjustments.

Professional installers drill strategic holes in wall cavities, insert application hoses, and monitor fill density using calculated pounds per cubic foot. Proper density ensures the insulation won’t settle and create gaps over time. For existing homes, this process requires careful planning to minimize cosmetic impact while maximizing protection.

Things to Consider Before Making a Decision

Before proceeding with blown-in insulation for freeze protection, evaluate several key factors:

- Existing Insulation Condition: Assess current insulation levels and determine if blown-in will supplement or replace existing materials

- Access Requirements: Some locations may require the temporary removal of siding or drywall for proper access

- Moisture Issues: Address any existing water infiltration problems before installing insulation

- Budget Constraints: Calculate return on investment based on potential damage costs versus installation expenses

- Local Building Codes: Verify requirements for vapor barriers and fire ratings in your area

The U.S. Energy Information Administration reports that homeowners who invest in proper insulation typically save between 10% and 50% on heating and cooling costs, providing additional financial benefits beyond freeze protection.

Regional Climate Adaptations

Climate zone significantly impacts insulation requirements for freeze protection. Homes in Zone 5-7 (Northern U.S.) need higher R-values and more comprehensive coverage than those in Zone 3-4 (Southern regions).

For homes in extreme cold regions (Zones 6-7), consider additional measures such as heat tape in combination with insulation for particularly vulnerable runs. The International Association of Certified Home Inspectors recommends minimum R-38 in attics and R-13 in exterior walls for these regions, though achieving these levels in existing construction may require cavity fill plus additional approaches.

In milder climates (Zones 2-4), focus on protecting against occasional cold snaps rather than sustained freezing temperatures. This often means targeted insulation of known vulnerable areas rather than whole-house approaches. The key is preventing the temperature around pipes from dropping below freezing for extended periods, not necessarily maintaining warm temperatures throughout the entire structure.

Key Takeaways for Freeze Protection

Blown-in insulation provides reliable pipe freeze protection when properly applied to vulnerable areas, creating continuous thermal barriers that keep pipes above freezing. The most successful approaches combine targeted insulation with other protective measures during extreme weather events. Consider your specific climate zone, existing construction details, and budget when planning installation.

Evaluate your home’s specific risk factors by identifying plumbing in exterior walls, crawl spaces, and unconditioned areas. Professional assessment can help prioritize areas needing immediate attention while planning a comprehensive protection strategy. The investment in proper insulation pays dividends through preventing damage and reducing energy costs year-round.

Get a Professional Assessment for Your Property

For homeowners needing expert evaluation of their freeze protection needs, Prestige Insulation Solutions offers comprehensive insulation assessments. The team can identify vulnerable areas, recommend appropriate materials, and provide professional installation services. Contact us at [email protected] or call (850) 429-4969 to schedule a consultation. Their experience with various climate zones and construction types ensures proper protection for your plumbing system.

Frequently Asked Questions

What is the minimum recommended R-value for pipe freeze protection?

For exterior walls containing plumbing, aim for R-13 to R-15 in cavity fill applications. Crawl spaces should have a minimum R-19 between joists, with additional protection for rim joists. These values may need adjustment based on your specific climate zone and pipe location.

How often does blown-in insulation need replacement?

Properly installed cellulose and mineral wool can last 20-30 years or more without replacement. However, in vertical applications, settlement may require adding more material after 5-10 years. Regular inspections help identify areas where density has decreased.

Does insulation attract pests or mold?

Modern insulation materials are treated with borates and other compounds that resist pests and inhibit mold growth. However, proper installation requires addressing any existing moisture issues to prevent problems regardless of insulation type.

Can insulation be added around existing pipes without opening walls?

Limited access is possible through small holes drilled from exterior or interior surfaces. However, complete cavity fill typically requires more extensive access for best results. Some newer technologies allow injection through smaller openings, but may not achieve the same density levels as traditional methods.

How does the financial investment for blown-in insulation compare to other freeze prevention methods?

Blown-in insulation requires a larger initial commitment than basic pipe wrapping, yet it remains significantly more economical than the extensive expenses associated with repairing burst pipes and water damage. This method also provides the added benefit of year-round energy efficiency, offering superior long-term value compared to simpler, localized solutions.

Sources

- Building Science Corporation – Research on insulation performance and heat transfer reduction in residential construction

- North American Insulation Manufacturers Association – Industry data on insulation material properties and performance specifications

- U.S. Energy Information Administration – Statistics on energy savings from residential insulation improvements