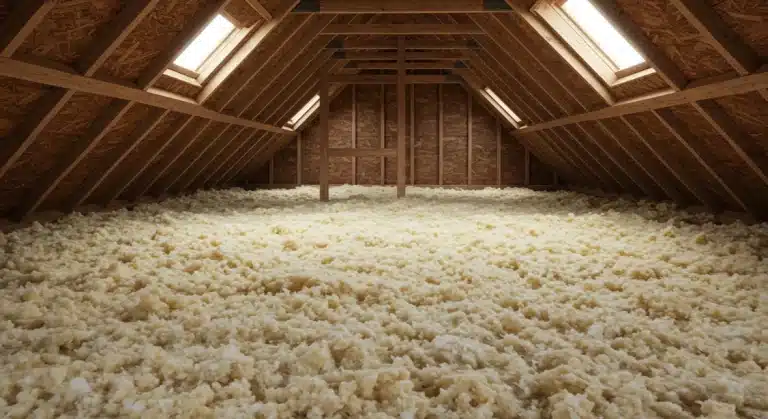

Consistency in blown-in insulation determines whether a home remains energy efficient or succumbs to excessive energy loss. When insulation is applied with uniform density, it creates a continuous thermal barrier that prevents heat transfer and blocks air movement. If the installation varies in thickness or density, thermal bridges form, allowing conditioned air to escape and outdoor air to enter. This lack of uniformity directly undermines the R-value rating of the material, meaning the home will not perform as expected, regardless of the quality of the insulation material used.

In Milton, Florida, where high humidity and intense heat are constant challenges, consistent insulation is non-negotiable. Prestige Insulation Solutions has observed that homes with uneven insulation often suffer from hot spots, higher utility bills, and moisture issues in the attic. The following information details why uniform application is technically necessary and how it impacts long-term home performance.

The Science of Insulation Density

Blown-in insulation, whether fiberglass or cellulose, works by trapping tiny pockets of air within a matrix of fibers. This trapped air resists heat flow. The effectiveness of this resistance depends entirely on the material being installed at the correct density. Density is the amount of material packed into a given volume.

If insulation is installed too loosely, the material settles over time. As it settles, the total depth decreases, and the R-value drops. This is often called “fluffing.” Installers might blow in extra material to make an area look deep initially, but without the proper weight per square foot, it will not hold its shape.

Conversely, if insulation is packed too tightly, it conducts heat through the fibers themselves, reducing its ability to insulate. This eliminates the necessary air pockets. Achieving the specific manufacturer’s density for the target R-value is the only way to ensure the material performs as intended.

Regional Challenges in Milton, FL

The climate in the Florida Panhandle presents specific challenges that make consistency even more critical. Milton experiences a hot-humid climate. During the summer, heat from the hot attic tries to penetrate the living space. In winter, the opposite occurs, though for shorter periods. More importantly, the humidity levels mean that air leakage brings moisture into the home.

If blown-in insulation is not consistent, gaps or low-density areas allow moist air to bypass the thermal barrier. When this warm, moist air hits a cooler surface within the wall or attic structure, condensation can form. Over time, this moisture promotes mold growth and wood rot. According to the U.S. Department of Energy, proper air sealing combined with consistent insulation is the best defense against moisture issues in humid climates.

Homes in Milton also face severe weather events, including hurricanes and tropical storms. High winds can drive rain through small openings in the building envelope. Consistently dense insulation helps plug these small gaps, acting as a secondary barrier against wind-driven moisture intrusion.

Performance Data and Efficiency Standards

Industry data supports the link between installation quality and energy savings. The Insulation Institute states that nearly 90% of homes in the United States are under-insulated. However, even homes with adequate insulation often fail to perform well due to poor installation practices. Gaps and voids in insulation can reduce the effective R-value of a wall assembly by as much as 50%.

This means that buying a high R-value product does not guarantee performance. A study by Energy Star emphasizes that proper installation is critical to achieving the labeled energy performance of a home. The table below illustrates how different density levels impact performance and long-term stability.

Material Density Comparison

| Material Type | Target Density (lbs/ft³) | Settling Expectation | Air Barrier Capability |

|---|---|---|---|

| Blown-in Fiberglass | 0.5 – 1.0 | Minimal to None | Low (Air permeable) |

| Blown-in Cellulose | 1.5 – 2.5 | Settles ~10-20% | Medium-High (Denser) |

| Closed Cell Foam | N/A (Applied wet) | None (Expands) | High (Air impermeable) |

Cellulose generally achieves a higher density than fiberglass when blown in, which makes it more resistant to air movement and settling. However, cellulose requires strict attention to moisture management during and after installation. The higher density creates a better seal but also means the installer must be careful not to overburden the drywall ceiling.

Common Installation Errors

Achieving consistency requires training and attention to detail. Several common errors lead to uneven coverage. One frequent issue is inadequate machine calibration. Blowing machines have adjustable settings that control the fiber-to-air ratio. If the machine pulls too much air and not enough material, the insulation enters the cavity too lightly. It looks fluffy and thick initially, but will settle significantly within months.

Another error involves blocking vents in the attic. While full coverage is the goal, installers must keep intake and exhaust vents clear to allow the attic to breathe. Covering soffit vents with blown-in insulation is a mistake that leads to poor attic ventilation and roof deck overheating.

Poor wiring and plumbing clearance is also a problems. The insulation needs to flow behind and around obstacles. If the installer sprays over wires and pipes without getting behind them, it leaves uninsulated pockets against the exterior wall. These voids act as thermal highways for heat transfer.

Things to Consider Before Making a Decision

Homeowners should evaluate several factors before choosing an insulation method or contractor. Understanding these points ensures the final installation provides the intended value.

- Verification of Bag Counts: Reputable contractors calculate the exact number of bags needed to achieve a specific R-value based on the attic’s square footage. Homeowners should ask for this calculation and verify that the installed number of bags matches the invoice.

- Depth Markers: The attic should have depth markers stapled to the joists or rafters before installation begins. These markers serve as a visual guide to ensure the insulation reaches the correct depth in every bay.

- R-Value Requirements: Determine the recommended R-value for Zone 2 in Florida. Current standards often recommend R-30 to R-60 for attics in this region. The thickness required to achieve this varies by material type.

- Air Sealing Priorities: Insulation works best when air leaks are sealed first. A contractor who mentions sealing gaps around pipes, chimneys, and recessed lights before blowing in insulation understands the importance of the building envelope.

Bonus Tips for Long-Term Performance

Proper maintenance ensures the insulation continues to perform. Homeowners should avoid storing heavy boxes on top of blown-in insulation in the attic. Compressing the insulation reduces its R-value. If storage is necessary, build a raised platform or use dedicated storage trusses that allow the insulation to retain its full depth underneath.

Additionally, check for pest damage. Rodents and insects can burrow through loose-fill insulation, creating tunnels that allow air movement. If signs of pests appear, address the pest issue and then fluff the affected insulation areas or add new material to restore density.

Another tip involves recessed lighting. Older “can” lights generate significant heat and can pose a fire risk if covered by insulation unless they are rated for insulation contact (IC). If the fixtures are not IC-rated, barriers must be built to keep the insulation at least three inches away from the fixture housing. This maintains safety but creates a thermal hole, so upgrading to IC-rated fixtures is often a better long-term solution.

Final Thoughts on Uniform Coverage

Consistency in blown-in insulation is not a minor detail. It is the defining factor between a comfortable home and an inefficient one. Uniform density ensures the material performs at its rated R-value, resists settling, and blocks air movement. For Milton residents facing high cooling costs and humidity, a well-insulated attic is the best defense against the elements. Proper installation techniques, verified bag counts, and attention to depth markers are essential markers of a job well done. Homeowners should prioritize installation quality over material price to ensure lasting comfort and savings.

Professional Assessment

Homeowners unsure about their current insulation levels or considering an upgrade should consult with a professional. Prestige Insulation Solutions can provide a thorough evaluation of attic conditions to determine if air sealing and additional insulation will improve home performance. Contact the team at [email protected] or call (850) 429-4969 to schedule an inspection and discuss options for achieving consistent thermal protection.

Frequently Asked Questions

What is the main sign of inconsistent insulation?

High energy bills combined with uneven temperatures in different rooms are the most common signs. Ice dams on the roof (though rare in Florida) or hot ceilings in summer also indicate poor thermal coverage.

How is density measured during installation?

Installers use a formula based on the weight of the bags and the coverage area. They may also use a measuring tool called a “density card” or rulers to check that the depth matches the weight applied per square foot.

Is cellulose or fiberglass better for Milton homes?

Cellulose is generally preferred in humid climates like Milton because its higher density restricts air flow better than standard fiberglass. However, fiberglass with a proper air seal is also effective. The choice often depends on budget and specific home construction.

Will new insulation fix a drafty house?

Insulation stops heat transfer, not air movement. If drafts are the issue, the home needs air sealing work around windows, doors, and penetrations. Insulation helps, but sealing the leaks is the primary fix for drafts.

How often should attic insulation be inspected?

It is wise to inspect the attic once a year. Look for animal activity, wet spots from roof leaks, or compression from stored items. Catching these issues early prevents long-term damage and efficiency loss.

Sources

- U.S. Department of Energy – Official guidelines on insulation types, R-values, and installation best practices.

- Energy Star – Information on energy savings, installation quality, and thermal performance standards.

- Insulation Institute – Industry resource providing technical data on insulation density, settling, and efficiency statistics.