R-value measures the ability of insulation material to resist heat flow. In the hot, humid climate of Broadview Farms in Pensacola, a higher R-value indicates greater effectiveness at keeping outdoor heat from penetrating your living space. For blown-in insulation in this region (Climate Zone 2), the Department of Energy recommends achieving an R-value between R-30 and R-60 in attics to maintain consistent indoor temperatures and reduce cooling costs.

Understanding this metric is the single most practical step a homeowner can take to improve energy efficiency. It is not simply about how thick the insulation looks, but how well the specific material stops thermal transfer. This guide examines the technical requirements for Florida homes and how blown-in materials perform under local conditions.

The Science of Thermal Resistance

The “R” in R-value stands for Resistance. It is a calculation of how well a two-dimensional barrier, such as a layer of insulation, resists the conductive flow of heat. Heat naturally moves from warmer areas to cooler areas. In Pensacola summers, the heat in your attic attempts to push through the ceiling into your air-conditioned rooms.

Insulation works by trapping pockets of air that slow down this transfer. A report from Energy Star indicates that proper R-values can reduce heating and cooling costs by an average of 15% to 20%. Effectiveness depends on the material type, thickness, and density.

Why Location Dictates Your Number

Building codes and energy recommendations vary significantly based on geography. Broadview Farms is located in Pensacola, which falls under Climate Zone 2. This zone is characterized by high humidity and intense solar heat gain.

While a home in Michigan needs insulation to keep heat in, a home in Broadview Farms needs insulation primarily to keep heat out. The thermal pressure is reversed. If the R-value is too low, your HVAC system runs continuously to combat the heat radiating down from the attic. This constant operation leads to higher bills and premature equipment failure.

Market Data on Energy Loss

According to data published by the North American Insulation Manufacturers Association, roughly 90% of U.S. homes are under-insulated. In older neighborhoods like Broadview Farms, insulation often settles over time or was insufficient by modern standards when installed initially. This gap between current R-values and recommended levels represents a major source of energy waste for local residents.

Blown-In Materials and Their Performance

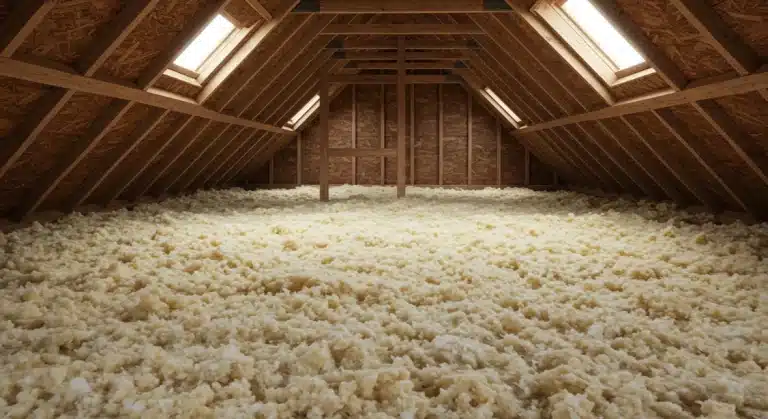

Blown-in insulation, also known as loose-fill, is particularly effective for Pensacola homes because it fills irregular gaps, corners, and spaces around wiring or ductwork that rolled batts might miss. The two most common materials are fiberglass and cellulose. Each achieves R-value differently.

Comparing Material Effectiveness

The table below outlines the amount of material required to achieve the target R-Value of R-38, a common standard for improving attic efficiency in Florida.

| Material Type | R-Value Per Inch | Est. Depth for R-38 | Key Characteristic |

|---|---|---|---|

| Blown-in Fiberglass | 2.2 – 2.7 | 14 – 17 inches | Lightweight, moisture-resistant, fire-resistant. |

| Blown-in Cellulose | 3.2 – 3.8 | 10 – 12 inches | Made from recycled paper, denser and settles over time. |

| Mineral Wool | 3.0 – 3.3 | 11 – 13 inches | High fire resistance, excellent sound dampening. |

Note: R-values per inch are approximate and can vary by manufacturer and installation density.

Bonus Tip: When checking your current insulation levels, use a ruler to measure the depth in several different spots. Insulation often piles higher in the center and thinner near the eaves.

Things to Consider Before Making a Decision

Simply adding more material to reach a specific number is not always the complete solution. Several factors influence the real-world performance of your insulation.

Air Sealing is Mandatory

Insulation resists heat flow, but it does not stop air flow. If there are cracks, holes around light fixtures, or gaps in the top plates of your walls, conditioned air will leak out regardless of the R-value. A study by the Oak Ridge National Laboratory suggests that air sealing combined with insulation is significantly more effective than insulation alone. The air leaks must be sealed before new blown-in material covers them up.

The Settling Factor

Blown-in cellulose tends to settle over time. What starts as 12 inches might compress to 10 inches after a few years, reducing the effective R-value. Fiberglass settles less but can be displaced by strong drafts if the attic is not properly baffled. When planning for R-38 or R-49, it is wise to install slightly more than the minimum requirement to account for future settling.

Moisture Management

In Broadview Farms, humidity is a constant variable. Wet insulation loses its R-value rapidly because water conducts heat far better than air. Ensure your roof has no leaks and that bathroom fans vent to the outside, not into the attic.

Common Misconceptions About R-Value

Many homeowners in Broadview Farms believe that doubling the R-value doubles the savings. This is incorrect due to the law of diminishing returns. The first few inches of insulation provide the most dramatic reduction in heat transfer. Going from R-0 to R-19 makes a massive difference. Going from R-38 to R-60 provides a smaller, though still beneficial, improvement.

Another misunderstanding is that all blown-in insulation is the same. As shown in the table above, density matters. You need nearly 50% more fiberglass depth to achieve the same resistance as cellulose. Space constraints in the attic might dictate which material is viable for your specific home.

Bonus Tip: Never block your soffit vents with insulation. This cuts off airflow, which can lead to superheated attics and moisture buildup. Use baffles to keep the air path clear.

Summary and Final Advice

The R-value is the primary yardstick for measuring insulation effectiveness, acting as a shield against the intense Florida heat. For residents in Broadview Farms, achieving an attic R-value between R-38 and R-60 is the standard for maintaining a comfortable, energy-efficient home. The choice between fiberglass and cellulose involves trade-offs regarding depth, density, and settling, but both offer substantial improvements over uninsulated spaces.

Evaluate your current attic depth, check for air leaks, and consider the long-term energy savings against the installation cost. Correctly installed insulation pays for itself through lower utility bills and reduced strain on your HVAC system.

Evaluating Your Home’s Efficiency

Taking control of your home’s thermal performance starts with an honest assessment of your current attic conditions. If you are unsure about your current R-value or need assistance calculating the proper depth for your specific layout, Prestige Insulation Solutions is available to help. Contact us at (850) 429-4969 or email [email protected] to discuss your options. Correctly addressing these factors today ensures lasting comfort for years to come.

Frequently Asked Questions

What is the ideal R-value for an attic in Pensacola?

For Climate Zone 2, which includes Pensacola, the recommended level for an uninsulated attic is R-30 to R-60. Most experts suggest aiming for at least R-38 to balance cost and energy savings effectively.

Can I blow new insulation over old insulation?

Yes, you can usually add new blown-in material over existing layers. However, the old insulation must be dry and free of mold. If the existing material is wet or damaged by pests, it should be removed first.

Does a higher R-value soundproof my home?

While the R-value measures thermal resistance, the material’s density contributes to sound damping. Blown-in cellulose and mineral wool generally offer better noise reduction than fiberglass due to their higher density, but R-value itself is not a measurement of soundproofing.

How long does blown-in insulation last?

When undisturbed and kept dry, blown-in fiberglass can last 80 to 100 years. Cellulose typically lasts 20 to 30 years before it degrades or settles enough to require topping off.

Sources

- Energy Star – Provides official recommended insulation levels for different climate zones across the United States.

- North American Insulation Manufacturers Association – Offers data on U.S. housing insulation statistics and material comparisons.

- Oak Ridge National Laboratory – A leading research institution providing studies on building envelope efficiency and air sealing.